2吨纯电动物流车一体式电驱动桥结构设计毕业论文

2020-02-17 12:48:46

Wuhan University of Technology Graduation Design (Thesis)

The structural design of the integrated electric drive axle of 2 tons pure electric logistics vehicles

School: School of International Education

Specialty amp; Class: Automotive Engineering gj1503

Name: Yang Xietian

Tutor: Qin Xunpeng

Statement of Degree Thesis originality

I solemnly declare:The thesis submitted is the research result independently obtained by myself under the guidance of my tutor. Except for the contents specifically quoted in this thesis, this thesis does not include any other works that have been published or written by individuals or groups. I fully understand that the legal consequences of this statement are borne by me.

Author’s Signature:

Date:

Using Authorization of Thesis copyright

The author of this thesis fully understands the provisions of the school regarding the protection and use of thesis, and agrees that the school retains and sends copies and electronic versions of the thesis to the relevant thesis management departments or institutions, allowing the thesis to be viewed and borrowed. I authorize the provincial excellent bachelor thesis selection institution to compile all or part of the thesis into relevant data for retrieval. The thesis can be saved and compiled by photocopying, printing or scanning.

The thesis belong to 1、Confidentiality囗,Apply this authorization after the year of declassification)

2、No Confidentiality囗 .

(Please type “√” in above relevant block)

Author’s Signature: Date:

Tutor’s Signature: Date:

Abstract

The mainstream trend in automotive research and development nowadays is electrification, and one of the keys to electrification for vehicle is the electrification of the drive axle. This design refers to the traditional truck drive axle design method, combined with the motor unit, to design a relatively reasonable integrated electric drive axle.

With the given data, design and analysis the overall parameters of vehicle. Determine the parameters of the motor to ensure that the power of the vehicle meets the needs of use. Determine the form of the final drive, choose the appropriate form to ensure that the structure of the drive axle is simple and small, design and calculate the reducer gears and check strength of it. Determine the form of the differential and do the design, calculation and strength check of the differential bevel gear. Select the suitable drive shaft, complete the design, calculation and strength check. Select the form of axle housing and combined with finite element analysis to check the strength of it.

After determining the parameters, use the modeling software CATIA to complete the 3D models about each parts ,export the 2D drawings, using CAD to modify and improve them. to ensure that the structure in the assembly drawing and part drawing is clear and complete.Finally, use the finite element analysis function of CATIA to complete the analysis of the electric drive axle about check strength and stiffness.

Key Words:electric drive axle; integrated design;CATIA;finite element analysis

Contents

Chapter 1 Introduction 1

1.1 The purpose and significance of research 1

1.2 Research Status at home and abroad 2

1.3 Main research content 3

Chapter 2 The design of electric drive axle 4

2.1 The design of drive axle assembly structure 4

2.2 Determination of the final drive 4

2.2.1 Dynamic requirements of pure electric logistics vehicles 4

2.2.2 Selection of motor parameters and final drive ratio 5

2.3 The design of final drive 6

2.3.1 The structure of final drive 6

2.3.2Main parameters of reducer spur gear transmission 7

2.3.3 Main parameters of spur gear transmission of two-speed final drive 10

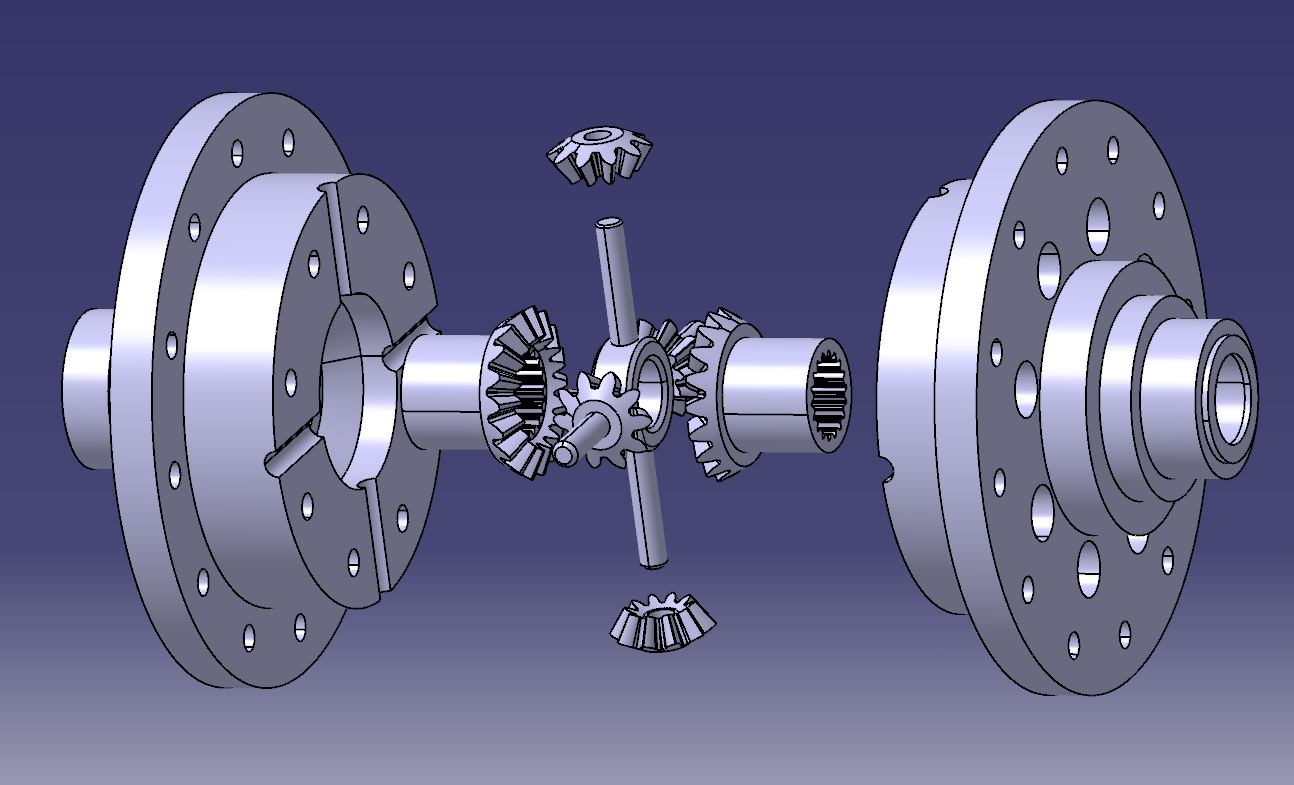

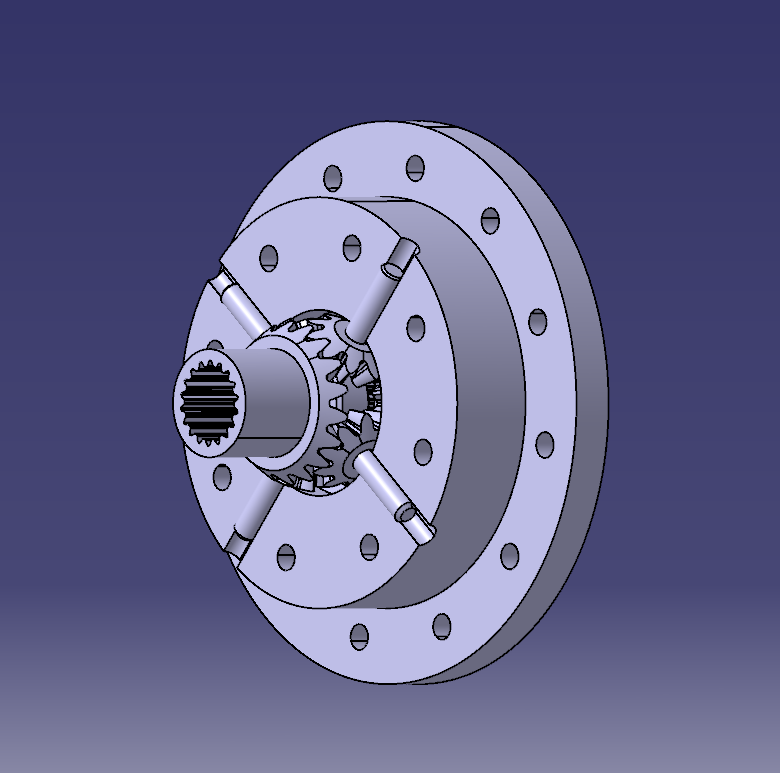

2.4 Design of differential 13

2.4.1 Structural form of the differential 14

2.4.2 Design of ordinary bevel gear differential gear 14

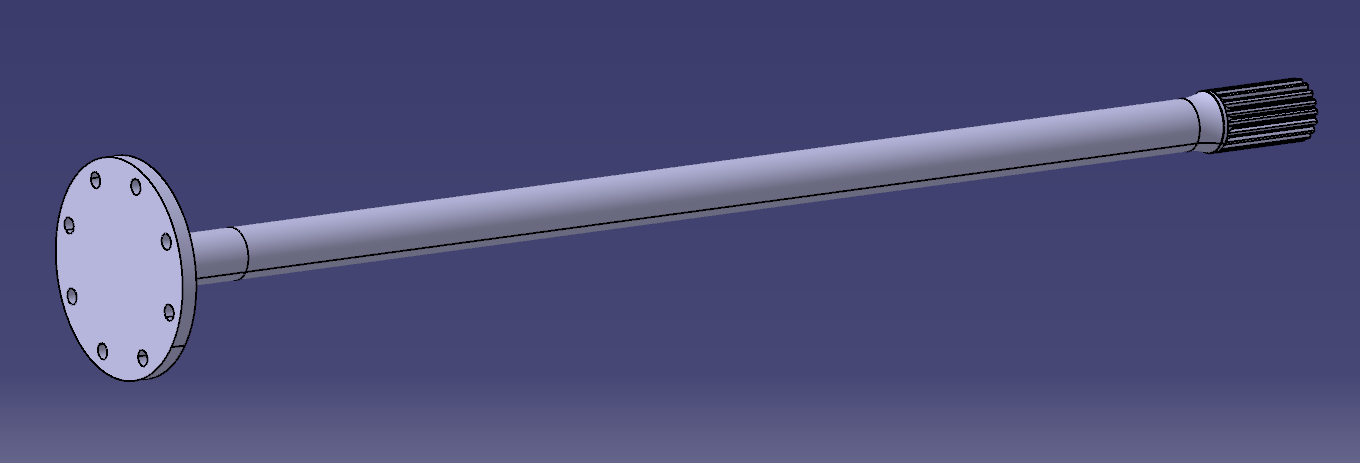

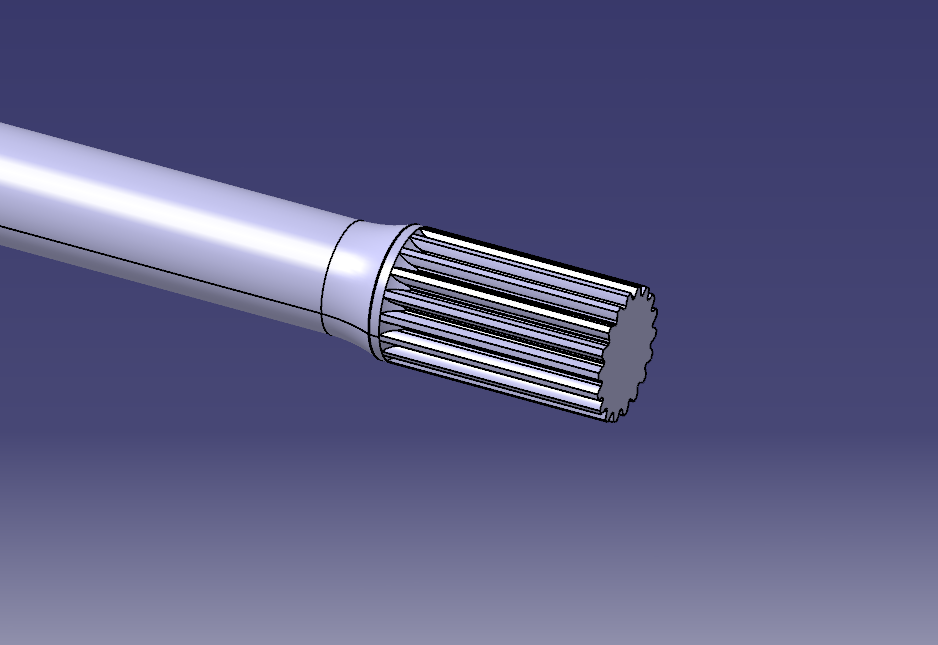

2.5 Design of drive shaft 17

2.5.1 Form analysis of drive shaft structure 17

2.5.2 Structural design of full floating drive shaft 19

2.5.3 Strength calculation of full floating drive shaft 19

2.6 summary 20

Chapter 3 CATIA 3D modeling 21

3.1 Introduction of software CATIA 21

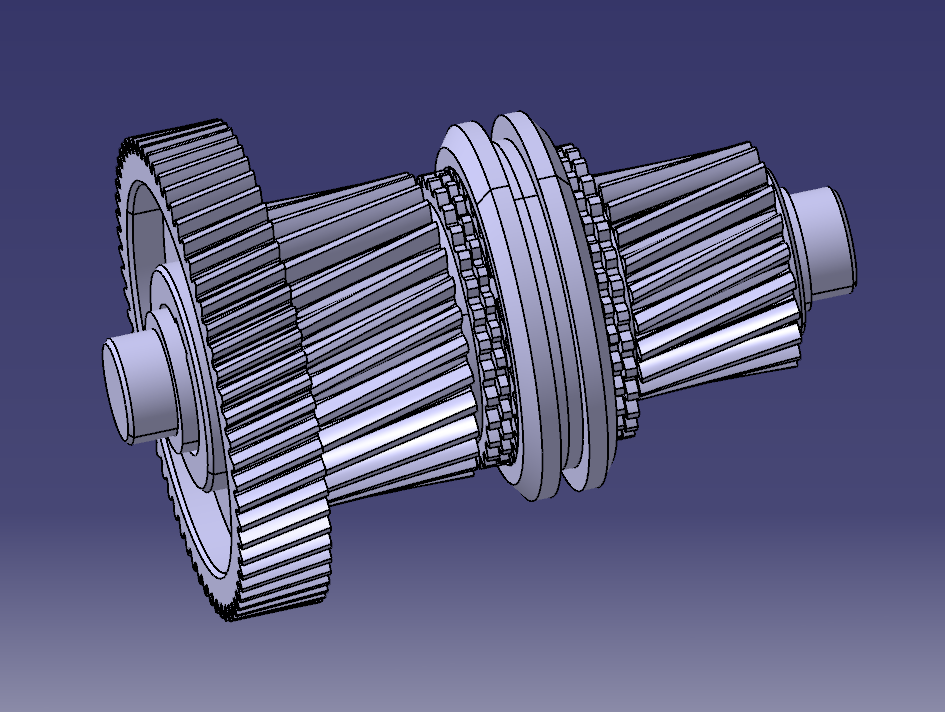

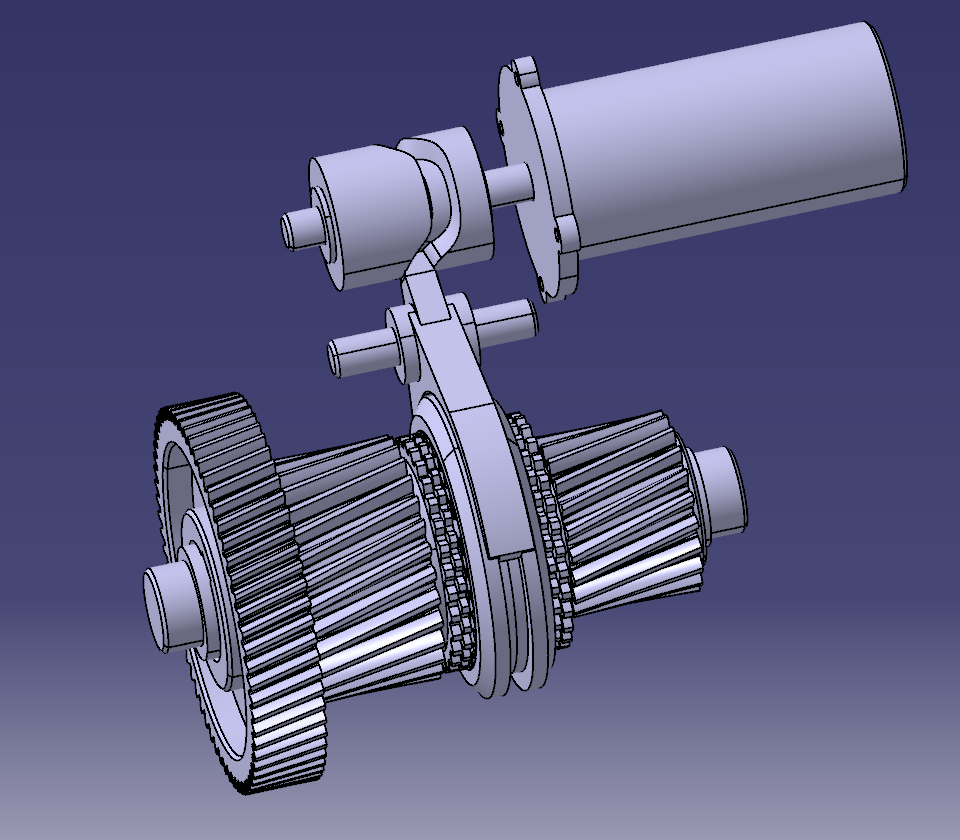

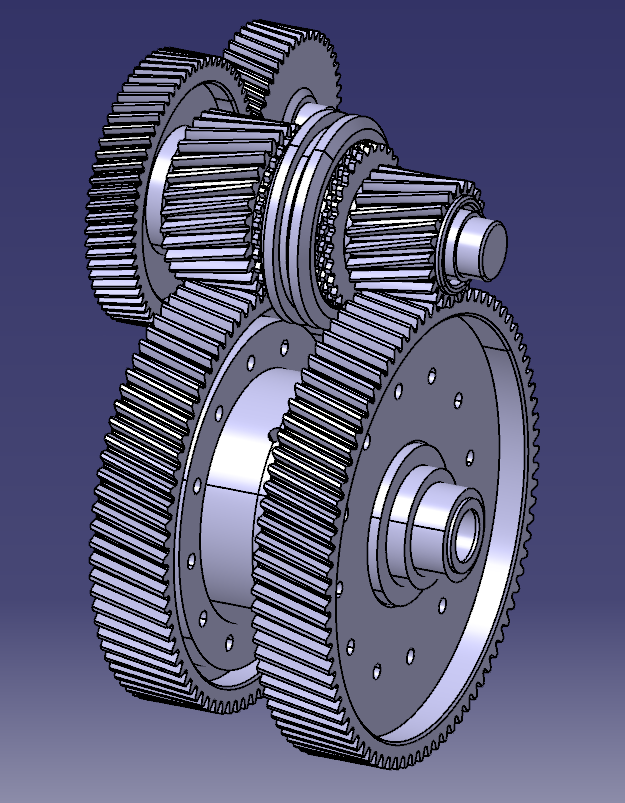

3.2 Modeling of final drive 21

3.3 Modeling of differential 21

3.4 Modeling of drive shaft 24

3.5 Modeling of drive axle housing 25

3.6 Modeling of drive axle 27

3.7 Summary 28

Chapter 4 Finite element analysis of drive axle housing 29

4.1 Constraint and force analysis of drive axle housing 29

4.2 Limitations of calculation methods 29

4.3 Establishment of finite element model 29

4.4 Material properties and meshing 29

4.5 Static strength analysis of drive axle housing 30

4.5.1 Introduction 30

4.5.2 Maximum vertical force condition 30

4.5.3 Maximum traction condition 32

4.5.4 Maximum braking force condition 33

4.6 Summary 35

Conclusion 36

References 37

Acknowledgement 39

Chapter 1 Introduction

1.1 The purpose and significance of research

The drive axle is located at the end of the drive train in vehicle, in order to increase the torque transmitted from drive shaft or directly from the transmission, distribute the torque to the left and right drive wheels and provide the wheels with the the differential function to fulfil requirements of the vehicle's driving dynamics.At the same time, the drive axle is withstood to forces between the road surface and the frame such as vertical forces, longitudinal forces and lateral forces.In a typical automotive structure, the drive axle includes a final drive, a differential, driver shafts, and a axle housing etc.

The key to the design of the drive axle is to correctly determine the structural form of the above-mentioned components and successfully combine them into an integral whole. The research and development of the drive axle is very important for the vehicle, the performance of the drive axle will directly reflect the rationality of the vehicle design.In the design and manufacture process of the drive axle, it is necessary to ensure that the quality of the drive axle cannot be too large, otherwise it will not only increase the production cost, but also reduce the economical efficiency of the vehicle.

The subject of this design is the structural design of the integrated electric drive axle of 2 tons pure electric logistics vehicles. With the continuous development of the automobile industry and the continuous improvement of technology, it brings great convenience to human beings but brings about three major problems about energy, safety and environmental protection. In order to effectively solve the problem of energy and environmental pollution, the change of automobiles from traditional fuel vehicles to electric vehicles is an certain choice in history. As the key of modern logistics, logistics vehicles need to obtain higher working capacity with a lower cost.The electrification of logistics vehicles can fulfill the dynamic requirements of logistics vehicles on the premise of fulfill energy saving. Integrating the motor, the speed reduction mechanism and the drive axle into one unit to reduce the volume of the electric drive axle, it is beneficial to the arrangement and weight reduction of the whole vehicle, and at the same time it can improve the transmission efficiency.

In the current automotive industry, CAD and CAE have been widely used, such as computer software AutoCAD, CATIA, etc.At the same time, in the drive axle design, combine the finite element method and the optimized design to the drive axle design can save the manpower, material and time, therefore, the optimal design can be obtained with the improved design efficiency, reduced the design cycle, reduced the production cost, and the improved electric drive. The reliability and economy of electric drive axle can be improved.

1.2 Research Status at home and abroad

Whether in the daily life of the people or in modern social transportation or in the economic production , the automobile and automotive industries plays important part in these.In recent years, the growth of the automobile industry has obviously slowed down. Although the automotive industry is at a relatively high level in Chinese machinery industry, there are still problems in which development cannot fulfill the demand.Chinese automotive industry started late, and the development level of various industrial chains is relatively backward.For example,although China already has a relatively complete design and manufacturing process of drive axle,however, the research and development of the drive axle is relatively weak, and there is still a big gap compared to the foreign level. The design of drive axle design is a bit conservative, it is still in the stage of analog design and experience design, lack of core technology, which also limits the improvement of the performance of the drive axle and the reduction of the production cost of the drive axle.

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: