6t纯电动轻型载货驱动桥设计毕业论文

2020-02-17 12:47:54

ABSTRACT

The main content of this literature is the process of the design and calculation of the drive axle for pure electric light truck.

As one of main component of vehicle drive line, its basic effect is to enlarge the torques that comes from the drive shafts or directly from the transmission, and distributes the torques to side wheels, and make the side wheels have the differential drive axle has an important effect on vehicle performance, therefore, we should keep a serious and earnest attitude during the course of design.

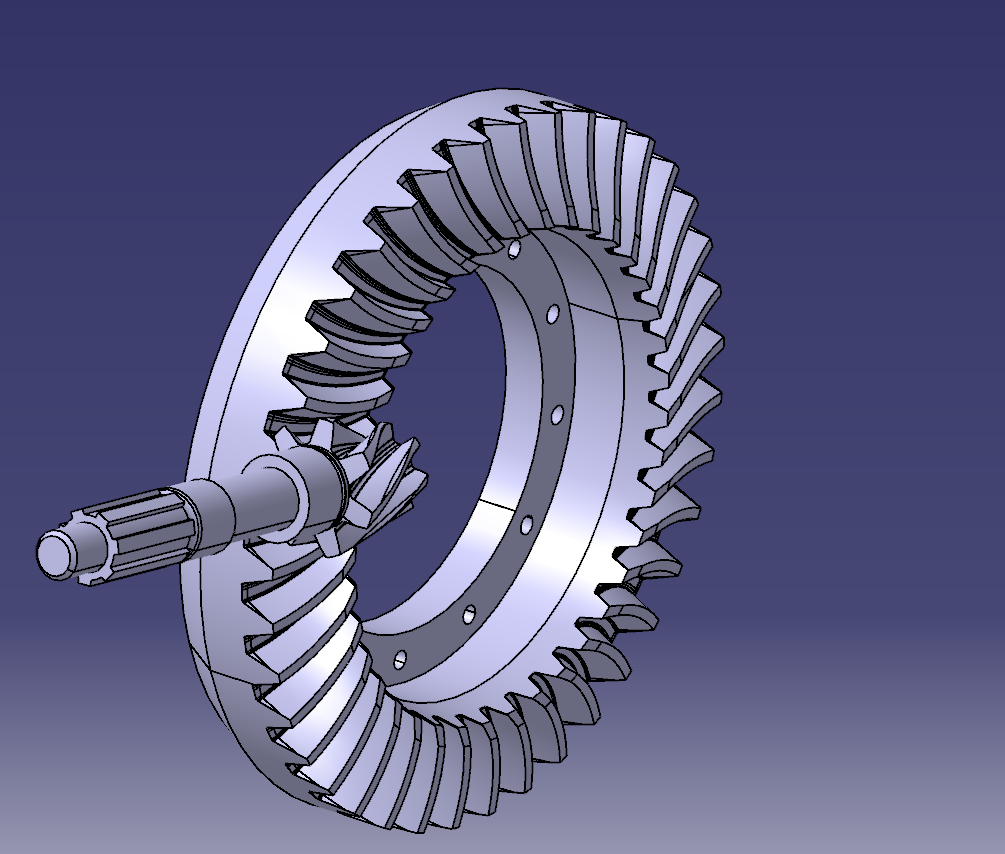

In the part of selection and argumentation ,a concrete description of structure form of drive axle and its assemblies are made. In this design, it has selected the single-grade main-reducer drive axle, it is two hypoid gears, it can simplify the structure, reduce the size, make effect use of the space and materials, reduce the whole quality..

In the part of designing conclusion and strength check, parameter of the essential units such as the speed reduction,differential,wheel drive mechanism and so on are selected. At the same time, the author makes the strength check to the main speed reduction,differential wheels drive mechanism.

Key words :drive axle ,Pure electric light truck ,differential gear, main-reducer

Contents

Absract 1

Chapter 1 Introduction 1

1. 1Purpose and significance (including analysis of research status at home and abroad) 1

1.1.1 research background 1

1.1.2 research status abroad 1

1.1.3 domestic research status 2

1.1.4 research objective 3

1.1.5 research significance 3

1.2 The basic content, objectives, the proposed technical scheme and measures of Research(design) 3

1.2.1 basic contents of research (design) 3

1.2.2 research objectives 4

1.2.3 technical plans and measures to be adopted 4

1.3 Research (design) objective parameters and overall scheme selection 4

Chapter 2 Analyzes the Structural Scheme of Drive Axle 6

Chapter 3 Design of main Reducer Gear 7

3.1 structure of main reducer 7

3.2 supporting form and placement method of main reducer driving bevel gear 8

3.3 Part of the parameters of the truck 8

3.4 Determination of the main reduction radio 9

3.5 Determination of the calculated load of the final drive gear 10

3.5.1 Determination of the calculated load of the driven gear 10

3.5.2 Calculated torque of the driving gear 12

3.6 Selection of basic parameters of main reducer gear 12

3.6.1 Selection of the number of teeth of the main and driven gears 12

3.6.2 Selection of pitch diameter and end modulus of driven gear 13

3.6.3 Selection of tooth width F of hyperboloid gear 13

3.6.4 Hypoid pinion offset and direction selection 14

3.6.5 Choice of helix angle β 14

3.6.6 Selection of normal pressure angle α 14

3.7 Strength calculation of hypoid gears 15

3.7.1Strength calculation of hypoid gears 15

3.7.2 Active bevel gear strength check 15

3.7.3 Follower bevel gear strength check 16

3.7.4 Tooth tooth contact strength 16

3.8 Main reducer gear material and heat treatment 17

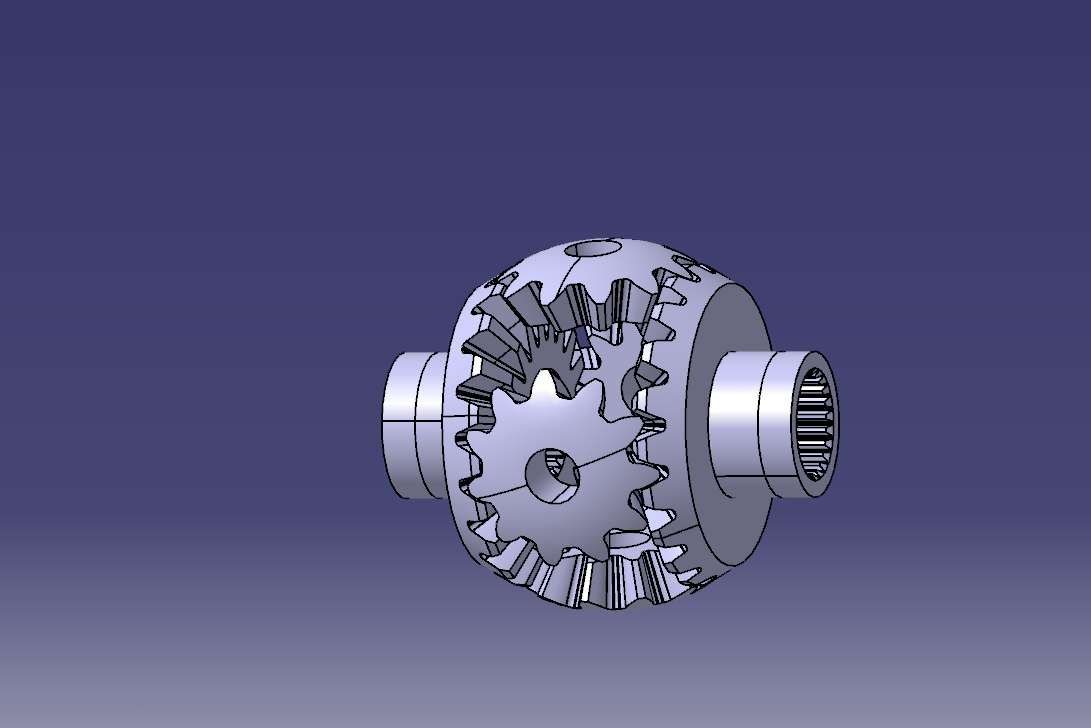

Chapter 4 Design of the Differential 17

4.1 Basic parameter selection of differential gear 18

4.1.1 Choice of the number of planetary gears 18

4.1.2 Planetary gear spherical radius selection 18

4.2 Selection of the number of teeth of planetary gears and half shaft gears: 19

4.2.1 Selection of the number of teeth 19

4.2.2 Preliminary determination of bevel gear modulus of conical planetary gear differential and pitch diameter of half shaft gear 19

4.2.3 pressure angle 20

4.2.4 Planet gear mounting hole diameter and depth 20

4.3 Differential gear strength calculation 20

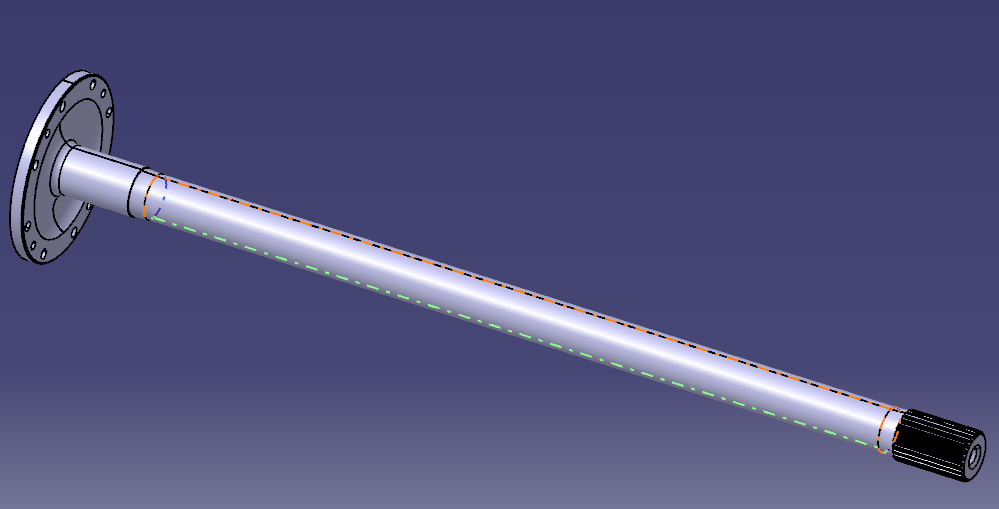

Chapter 5 Drives for Driving Wheels 21

5.1 Semi-axis structure type analysis 21

5.2 Half-axis design calculation 22

5.2.1 Primary selection of full floating half shaft diameter 22

5.3 Strength check 23

5.3.1 The torsional shear stress of the half shaft 23

5.3.2 The twist angle of the half shaft 23

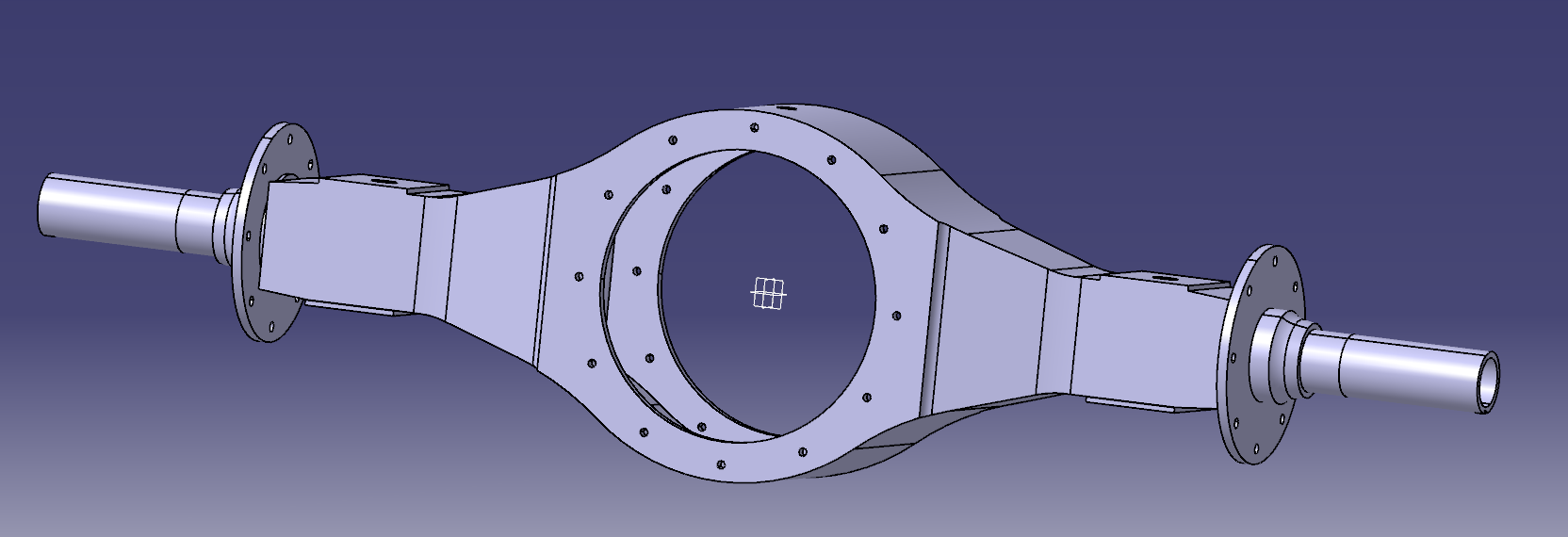

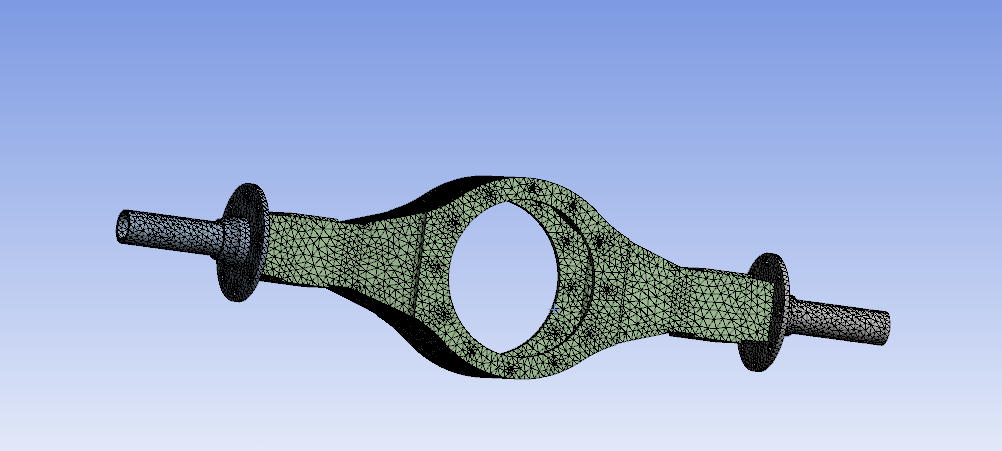

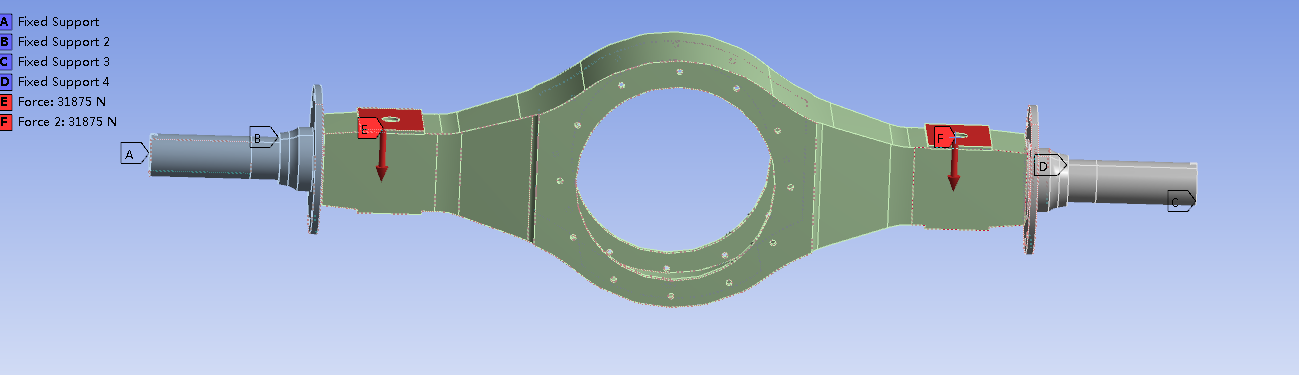

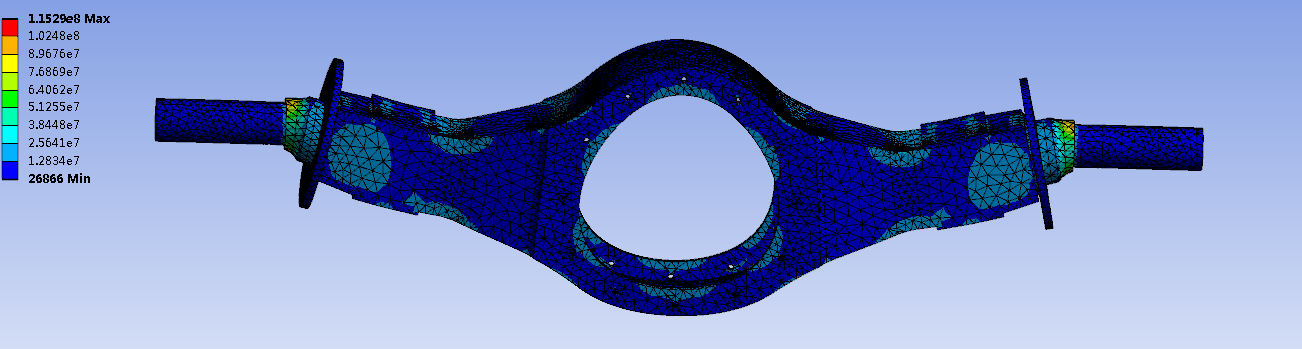

Chapter 6 Drive Axle Housing 24

6.1 Drive axle shell structure analysis 24

6.2 drive axle housing strength analysis 25

6.2.1 Strength analysis of drive axle housing 25

6.2.2 Modal analysis of drive axle housing 27

6.3 Analysis Conclusion 30

Conclusion 32

Reference 33

Thanks 34

Chapter 1 Introduction

1. 1Purpose and significance (including analysis of research status at home and abroad)

1.1.1 research background

Pure electric vehicles are the only vehicles in the world that can achieve zero emissions. Due to the requirements of environmental protection and the development of new materials and technologies, the research and development of pure electric vehicles is a strategic choice to realize the leapfrog development of Chinese engineering technology and an important choice to realize the sustainable development of Chinese automobile industry[1]. For the research and development of new energy vehicles, China can seize such an opportunity to vigorously study and develop electric vehicles, which will hopefully reach the world's advanced level in this field and form a new growth point of China's pillar[2] .

Electric vehicle drive axle is an important part of the power system of electric vehicle, which plays a vital role in the smooth and efficient transmission of power to the wheel hub. In the whole power system at the end of the position, its basic functions are: (1) the universal transmission device from the engine torque through the main reducer, differential, half shaft to drive the wheel, achieve speed reduction increase torque; (2) change the torque transfer direction through the main reducer bevel gear pair; (3) through the differential to achieve the two sides of the wheel differential effect, ensure that the inner and outer wheels with different speed steering; (4) through the bridge housing and wheel, the bearing capacity and passing torque function are realized. And the main reducer, differential, half axle, drive axle housing and other main components of the drive axle and many different structures.[3] For example, the main reducer is divided into single stage, double stage, double speed, wheel edge reducer, etc. Therefore, in the case that our design goal is based on 6t pure electric truck, the correct selection of the structure and parameters of the drive axle according to the different properties of the motor and the fuel engine has become the main problem that we need to study in this project.

1.1.2 research status abroad

Compared with the domestic market, the electric vehicle market in foreign markets is relatively mature, and the market environment is more favorable for the commercialization of electric vehicles. European and American countries also prefer pure electric vehicles with lower pollution. Therefore, under the leadership of Germany and other automobile powers, the development of pure electric vehicle technology has a bright development prospect[15].

Compared with the domestic focus on the optimization of the existing drive axle, foreign studies pay more attention to the matching of the drive axle and suspension and the research of new materials of the drive axle and suspension. In Western Europe, only 40% of cars have dual-stage reducer with wheel-edge deceleration. The reason is that the road conditions in Western Europe are relatively good, and the cost of adopting single-stage deceleration and double-stage curved spiral bevel gear pair is relatively low, so most of them adopt this structure. Besides, foreign drive axle adopts advanced technologies such as limited slip differential and wet driving brake, which can greatly reduce the wear of tires and improve the safety performance of the whole vehicle, and is convenient for maintenance. However, due to the relatively high cost of limited slip differential and other components, it has not been widely used in China.

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: