纯电动乘用车同轴一体化驱动桥设计毕业论文

2020-02-17 12:47:43

摘 要

纯电动汽车能达到零排放的状态。基于环境保护的要求及新材料和新技术的发展,纯电动汽车的研发是能够实现中国工学技术快速发展的战略抉择,也是实现中国汽车工业能够可持续发展的重要途径。对于纯电动汽车的研制,若我国能抓住这样的契机,大力研究发展该项产业,必将有希望在这一领域跻身世界前列,从而形成我国支柱的新增长点。

该同轴电动驱动桥结构紧凑,体积小,传动效率高,成本低。它是一种机电一体化驱动系统,专为纯电动汽车的结构布局和传动特性而设计。因此,它更多地用于小型和轻型电动车辆。然而,随着乘用车需求的不断增加,在使用电动乘用车的过程中问题变得越来越突出,所得到的解决方案,特别是后桥整合的趋势尤为明显。作为纯电动汽车的主要载体和传动部分,为了尽可能地减小空间容量,为了便于电动汽车电池组的布置,并且要求更大的尺寸,整合需要结构驱动后桥。传动效率为了改善电动车辆的续航里程,必须具有大的负荷以满足电动车辆的需求。因此,如何设计满足上述要求的纯电动客车的电驱动后桥是首要任务。因此,本主题探讨了用于纯电动汽车的同轴集成驱动桥的设计。

本文的研究对象是东风风神E70 2019款EV,通过对该款汽车的研究设计出一款满足该汽车的同轴一体化驱动桥。最后对其进行许用应力的分析,从而验证此项设计的合理性。

首先,有必要了解电动汽车的驱动系统和现有电动汽车的驱动桥,然后重新设计和优化现有的驱动桥,并利用原理设计和构建新的同轴集成驱动器。基于电驱动桥的新配置,结合所选车辆的实际参数,匹配和选择驱动电机和传动系统的参数。 建立了匹配电驱动后桥的三维几何模型。其次,对所涉及的纯电动车同轴一体化驱动桥进行各种结构参数的设计,并通过所选取的电动机的最大转速和额定转速来确定应该使用何种传动系统,最后对所设计的传动系统进行剪切应力、扭转应力的校核,来检测其是否满足在该条件下的要求。其中材料力学等课程的知识需要被运用到。

再次,对所涉及的纯电动汽车同轴一体化驱动桥进行模型的构建,需要应用到的软件有CATIA等,依照上述所设计的尺寸进行零件的设计和最终的装配。随后对以设计的模型进行仿真优化,来验证本次设计的可行性。

最后,基于本次毕业设计的成果进行最终的二维图形的导出和产品特征的描述。

关键词:纯电动乘用车 同轴一体化驱动桥 电动机 传动系统

Abstract

With the rapid development of economic globalization and the continuous advancement of industrial technology in various countries, the automobile industry is in a state of rapid development. With the increasing number of cars, a large amount of fossil energy is consumed, causing serious environmental pollution problems, which have been seriously jeopardized. It is the daily life of people. Pure electric vehicles are currently the only vehicles in the world that can achieve zero emissions. Due to the requirements of environmental protection and the development of new materials and new technologies, the research and development of pure electric vehicles is a strategic choice to realize the leap-forward development of China's engineering technology, and is also an important choice for the sustainable development of China's automobile industry. For the development of new energy vehicles, China can seize this opportunity and vigorously study and develop electric vehicles. It is bound to hope to reach the world's advanced level in this field and form a new growth point for China's pillars.

The coaxial electric drive axle has the advantages of compact structure, small volume, high transmission efficiency and low cost. It is an electromechanical integrated drive system designed for the structural layout and transmission characteristics of pure electric vehicles. Therefore, it is suitable for use in miniature electric vehicles. However, as the demand for commercial vehicles continues to increase, problems in the use of pure electric commercial vehicles become more prominent, and rear axle integration is particularly noticeable. As the main carrier and transmission part of the pure electric vehicle, in order to reduce the space capacity as much as possible, to facilitate the arrangement of the electric vehicle battery pack, and to require a higher size, the integration requires the structure to drive the rear axle. Transmission efficiency In order to improve the cruising range of an electric vehicle, it is necessary to have a large load to meet the cargo demand of the electric vehicle. Therefore, how to design an electric drive rear axle of a pure electric commercial vehicle that meets the above requirements is a top priority. Therefore, this topic is based on the design of a coaxial integrated drive axle for pure electric passenger cars.

The research object of this paper is Dongfeng fengshen 2018 EV. Through the research of this car, a coaxial driver that satisfies the car is designed. Finally, the analysis of the allowable stress is carried out to verify the rationality of the design.

First of all, it is necessary to understand the drive system of the electric vehicle and the drive axle of the existing electric vehicle, and then redesign and optimize the existing drive axle, and propose a coaxial integrated electric drive based on the existing drive rear axle. The configuration of the rear axle. Based on the new configuration of the electric drive rear axle, combined with the actual vehicle model parameters of the vehicle, the parameters of the drive motor and the drive train are matched. The three-dimensional geometric model of the matched electric drive rear axle is constructed.

Secondly, the various structural parameters of the pure electric vehicle coaxial integrated drive axle are designed, and the selected transmission system is determined by the rated speed and maximum speed of the selected motor. Finally, the designed transmission system is designed. The shear stress and torsion stress are checked to determine if they meet the requirements of this condition. It needs to be applied to knowledge of material mechanics.

Thirdly, the model of the pure electric vehicle coaxial integrated drive axle involved is constructed. The software to be applied is CATIA, etc., and the design and final assembly of the parts are carried out according to the dimensions designed above. The simulation of the designed model was then carried out to verify the feasibility of the design.

Finally, based on the results of this graduation design, the final two-dimensional graphics are exported and the product features are described.

Keywords: Pure electric ;vehicle coaxial integrated drive axle;electric motor;transmission system

目录

摘要 1

第一章 绪论 6

1.1论文的选题背景和意义 6

1.2国内外研究现状 6

1.3论文目的与意义 6

1.4论文的设计对象 7

1.5论文的基本概括 7

第二章 电动汽车同轴一体化驱动桥参数设计 8

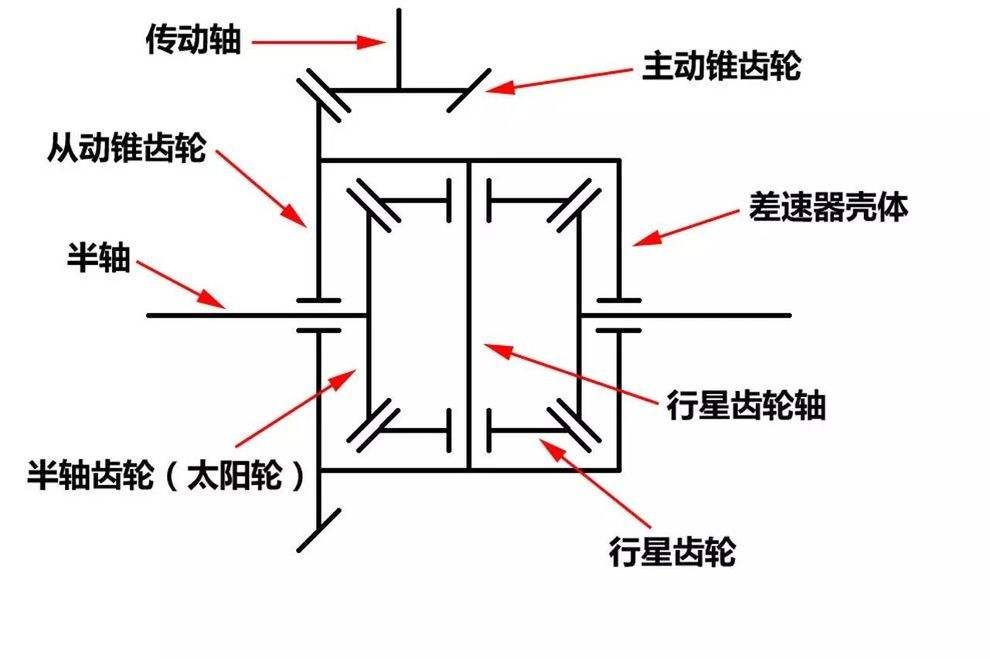

2.1电动汽车同轴一体化驱动桥结构分析 8

2.2电动汽车同轴一体化驱动桥参数设计 9

2.3本章小结 14

第三章 驱动桥的三维模型 15

3.1电动机三维示意图 15

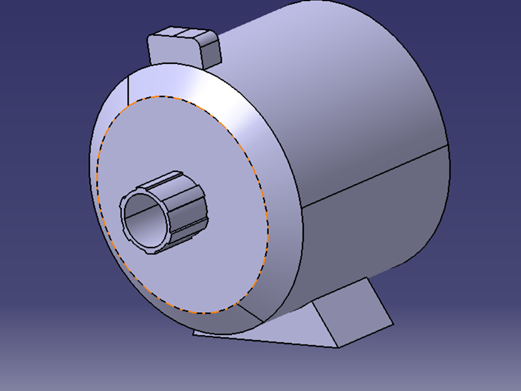

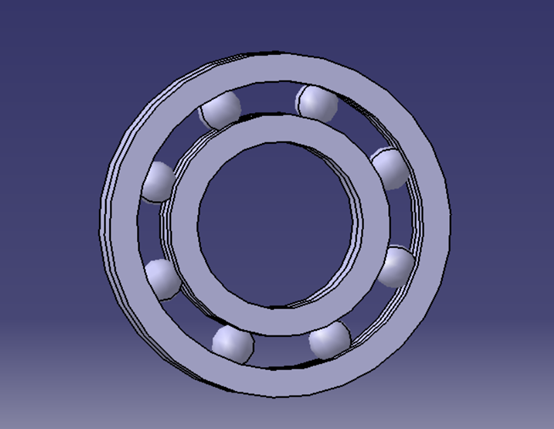

3.2轴承三维示意图 15

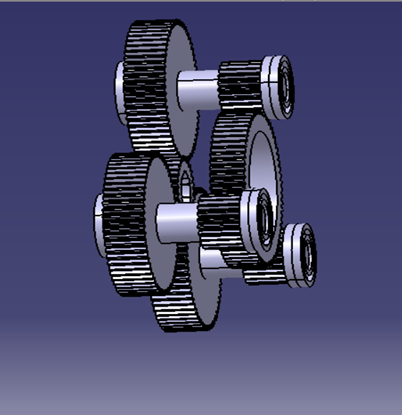

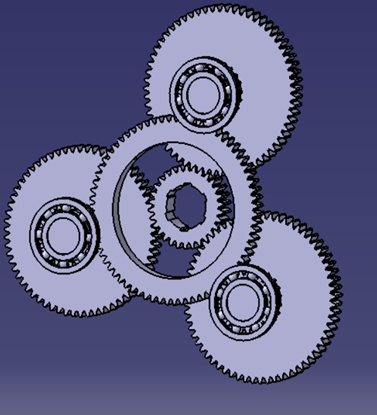

3.3行星齿轮系的三维模型 16

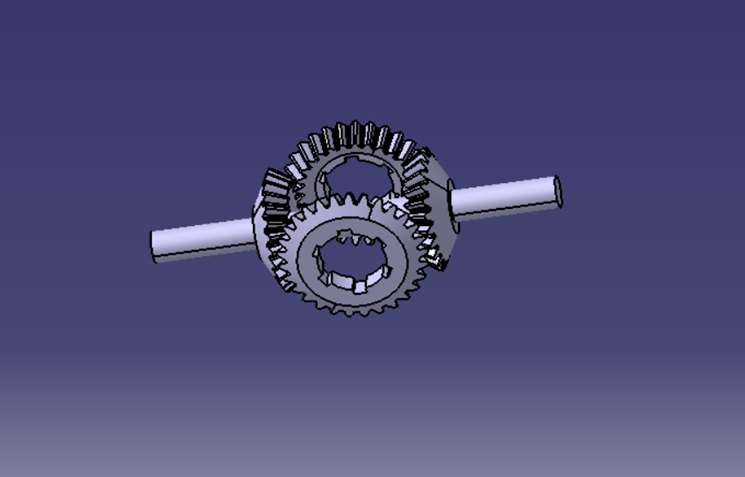

3.4差速器三维模型 17

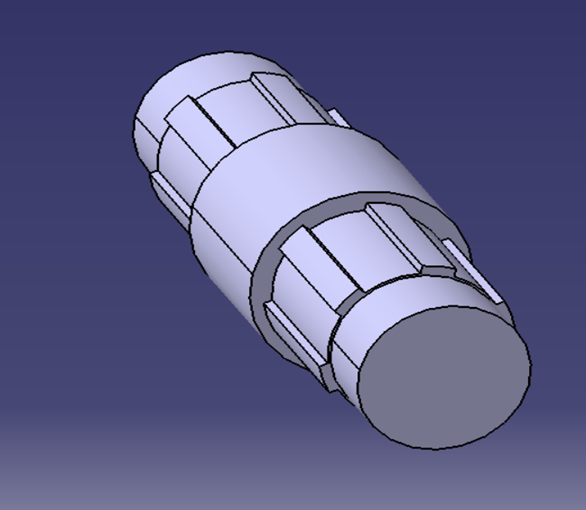

3.5花键的三维示意图 17

3.6传动系实体模型 18

3.7外壳图 18

3.8驱动桥大致模型 19

3.9分解零件图 19

3.10本章小结 20

第四章 系统应力分析 21

4.1齿轮系应力分析 21

4.2轴承应力分析 21

4.3本章小结 23

第五章 驱动桥静应力分析 24

5.1花键轴的校核 24

5.2啮合齿轮的校核 24

5.3本章小结 26

第六章 总结与展望 27

致谢 28

第一章 绪论

1.1论文的选题背景和意义

在21世纪,随着环境条件的恶化与人们环保意识的觉醒,在以燃料汽车为主导的汽车界,纯电动汽车凭借其环保与节能等优点逐渐杀出重围,并且在整个汽车界中所占的比例越来越大。并且由于历史的原因,我国与传统汽车工业强国还存在较大的差距,所以对于汽车产业存在较大的扶持,希望在插电混动汽车这一领域能够实现对先进国家的弯道超车,早日实现称为汽车制造大国的强国梦。

而对于新能源汽车此处特指插电式混合动力汽车而言,相对于传统的以汽油、柴油为燃料的机动车,其具有结构简单、低碳环保、高效节能等优点,在现有的燃油汽车的基础上各大公司都加大了对新能源汽车的布局,以求在未来的竞争中脱颖而出,成为这一领域的霸主。在2019年,纯电动汽车的增速仍然较快,具有广阔的前景。

基于此本篇论文以纯电动汽车驱动桥为研究对象,同时结合当前现状,设计一种一体化电驱动后桥,从而实现了同轴一体化的目标。

1.2国内外研究现状

新能源汽车的定义在不同国家其称谓也有所不同,在日本“低公害汽车”常常指代该类车型。在2001年所制定了“低公害车开发普及行动计划”中,该计划所指的低公害公车包括以下5类:以天然气燃料为燃料的汽车、具有混合动力的汽车、纯电动汽车、通过甲醇燃烧产生的能量驱动的汽车、通过严格排污和效率限制标准的清洁汽油汽车。在美国,“代用燃料汽车”就是新能源汽车的代称。

研发和推广新能源汽车已经是我国的重要国家战略,近些年在整车和电池、电机等关键零部件的研究上我国取得了很大的进展,并且制定了一些相关的生产、检测、试验国家和行业标准。

1.3论文目的与意义

石油紧缺和环境恶化的双重压力下,电动汽车预计在未来会完全取代如今普及的传统燃油汽车,但是在相当长的时间内纯电动汽车的充电时间较长、整车成本较为高昂、缺乏基础设备等问题仍然急需解决。随着电能使用比例的增加,插电式混合动力汽车(plug-in HEV,PHEV)的普及率会越来越高。

此篇论文的重点研究的就是插电式混合动力汽车,而所涉及驱动桥比较于传统驱动桥更为的轻便、紧凑。顺利解决了传统电动汽车电驱桥紧凑型布置所引起的倾覆力矩的问题,同时可以使汽车底盘变得更加的低,从而使汽车重心低增加汽车的操纵稳定性,便于驾驶员驾驶。

1.4论文的设计对象

该篇同轴一体化驱动桥的设计对象为电动乘用车,故选择东风风神E70作为基本参数的参考对象,对其进行研究。该车为2019款超享版,动力性能优良。

1.5论文的基本概括

第一章主要是对现阶段此项研究的总结与自己论文的设计对象的研究。

第二章是对所选车辆的研究,通过所给电动汽车的最大与额定功率、最高车速、电动机最大扭矩来确定电动汽车的最大与最小传动比。从而来设计所需行星齿轮与差速器、半轴的规格。

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: