商用车钢板弹簧悬架系统设计及其运动特性分析软件开发毕业论文

2021-11-28 21:25:26

论文总字数:73733字

Wuhan University of Technology Undergraduate Graduation Design (Thesis)

Design (Thesis) Title: Design of commercial vehicle leaf spring suspension system and development of its motion characteristic analysis software

School: School of International Education

Specialty amp; Class: Automotive Engineering gj1502

Name: Yang Peidong

Tutor: Hu Sanbao

Statement of Degree Thesis originality

I solemnly declare:The thesis submitted is the research result independently obtained by myself under the guidance of my tutor. Except for the contents specifically quoted in this thesis, this thesis does not include any other works that have been published or written by individuals or groups. I fully understand that the legal consequences of this statement are borne by me.

Author’s Signature:

Date:

Using Authorization of Thesis copyright

The author of this thesis fully understands the provisions of the school regarding the protection and use of thesis, and agrees that the school retains and sends copies and electronic versions of the thesis to the relevant thesis management departments or institutions, allowing the thesis to be viewed and borrowed. I authorize the provincial excellent bachelor thesis selection institution to compile all or part of the thesis into relevant data for retrieval. The thesis can be saved and compiled by photocopying, printing or scanning.

The thesis belong to 1、Confidentiality囗,Apply this authorization after the year of declassification)

2、No Confidentiality囗 .

(Please type “√” in above relevant block)

Author’s Signature: Date:

Tutor’s Signature: Date:

Catalog

Catalog 1

Abstract 3

Chapter 1 Introduction 1

1.1 Design background and significance 1

1.2 Overview of vehicle suspension 2

1.3 Current situation of China's automobile suspension development 5

1.4 Main contents of the study 6

Chapter 2 Basic parameters and scheme of design 8

2.1 Basic design parameters 8

2.2 Overall scheme demonstration 8

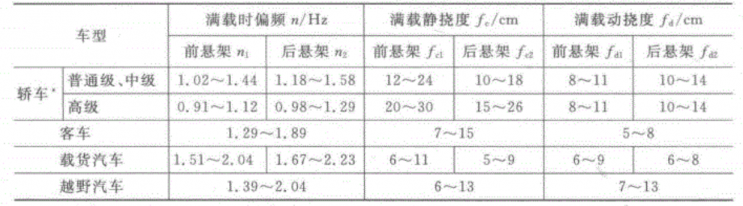

Chapter 3 Determination of main parameters 10

3.1 Calculation and selection of static deflection and dynamic deflection of suspension 10

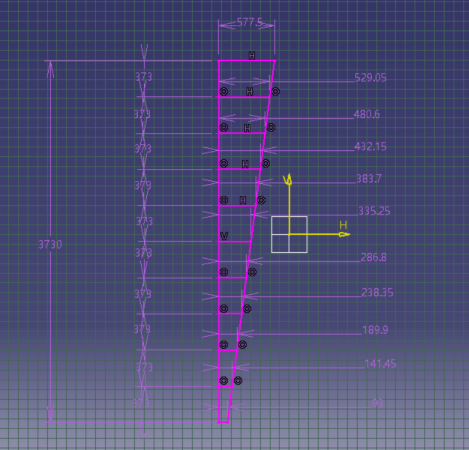

3.2 Calculation of average thickness and width of leaf spring 12

3.3 Determination of the length of each leaf of leaf spring 13

3.4 Calculation of arc height and curvature radius of leaf spring assembly in free state 16

3.5 Checking calculation of the strength of leaf spring 17

Chapter 4 Calculation of key parts 19

4.1 Spring pin design 19

4.2 Rolling ear design of main piece 19

4.3 Design of pressing plate and nut 19

Chapter 5 Design and calculation of shock absorber 21

5.1 Selection of relative damping coefficient ψ 21

5.2 Determination of damper damping coefficient 21

5.3 Determination of maximum unloading force F0 22

5.4 Selection of main dimensions of shock absorber 22

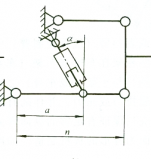

Chapter 6 Design and checking calculation of thrust rod 24

6.1 Optimization design of automobile thrust rod 24

6.2 Calculation of instability 24

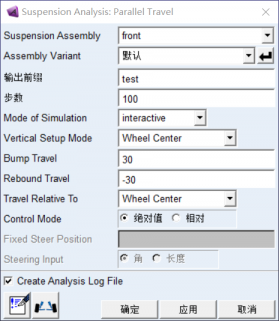

Chapter 7 Model simulation based on ADAMS 26

7.1 Selection of hard point coordinates 26

7.2 Simulation of two wheels running out in the same direction 26

7.2.1 Kingpin inclination 27

7.2.2 Caster angle of kingpin 28

7.2.3 Front wheel camber angle 28

7.2.4 Toe Angle of front wheel 29

Chapter 8 Programming of human-computer interaction design software package based on MATLAB 30

8.1 Static deflection and rigidity design calculation of suspension 30

8.2 Main size selection of shock absorber 32

Conclusion 34

Thank 35

Reference 36

Appendix 37

1. Damper size selection software code 37

2. Software code related to suspension elastic characteristics 47

Abstract

The structure of suspension consists of all the power transmission devices between car frame, axle and wheel. The automobile suspension mechanism is commonly composed of elastic elements, guide mechanism and shock absorber, among which the elastic elements include leaf spring, spiral spring and air spring. The function of automobile suspension mainly includes transmitting the force and torsion between the wheel and the frame, buffering the impact of the road on the body and reducing the vibration caused by it, so that the vehicle can run more smoothly.

This graduation dissertation aims to design the leaf spring suspension system of a certain type of commercial vehicle based on the knowledge of automobile theory and automobile construction, establish the three-dimensional model of leaf spring suspension with CATIA modeling software, check and simulate the relevant parameters with ADAMS simulation software, and compile the leaf spring suspension system design software with computer language to form a complete set the design software package of leaf spring suspension system with good man-machine interface. Therefore, the combination of knowledge and practice can train students' comprehensive quality.

Key words: leaf spring suspension, 3D modeling, simulation, MATLAB

Chapter 1 Introduction

1.1 Design background and significance

With the rapid development of modern automobile suspension, new suspension devices are emerging. Every span of suspension technology is closely related to the development of related disciplines, such as computer technology, automatic control technology, fuzzy control, neural network, advanced manufacturing technology, motion simulation and so on, which provide a strong guarantee for the further development of suspension. The development of suspension also puts forward higher theoretical requirements for related disciplines, and makes human cognition move to a new and higher realm.

On the one hand,using software to design the steel plate suspension system, and using ADAMS to simulate, calculate and mode it, , the result is accurate, easy to control and predict. On the other hand, it avoids the complexity and high cost of vehicle experiment, which has great engineering value and academic research significance, and is also a very popular and reliable method in related research fields,so it is widely used by scholars at home and abroad. Therefore, it can be concluded that this suspension related research will have greater engineering practical value and academic research significance, and its prospect also deserves greater expectation and prospect [1].

1.2 Overview of vehicle suspension

The suspension consists of elastic element, guide device, shock absorber, buffer block and lateral stabilizer. The guide device is composed of a guide rod system, which is used to determine the relative motion characteristics of the wheel to the frame (or body), and to transmit various forces and moments other than the vertical forces transmitted by the elastic elements. In the case of the longitudinal leaf spring being used as the elastic element, it also acts as a guiding device. The buffer block is used to reduce the direct impact of the axle on the frame (or body) and prevent excessive deformation of the elastic elements. The vehicle equipped with a lateral stabilizer can reduce the roll angle and lateral angle vibration of the vehicle body during cornering [2].

According to the structural characteristics of the guide mechanism, automobile suspension can be divided into two categories: non-independent suspension and independent suspension. The distinctive feature of non-independent suspension is that the left and right wheels are connected by a rigid beam or a non-disconnected axle. In the case of one side of the wheel passing through the bulge, it will directly affect the other side of the wheel. There is no such rigid beam in the independent suspension, and the left and right wheels are respectively "independently" connected with the frame or the body or form a broken axle. According to the structural characteristics, they can be subdivided into cross arm type, longitudinal arm type, diagonal arm type and so on [3].

Its main functions are as follows:

请支付后下载全文,论文总字数:73733字

相关图片展示: