MDEA对碳钢在含H2S环境下应力腐蚀的缓蚀性能研究毕业论文

2020-05-15 22:22:45

摘 要

随着我国科技与社会发展速度的快速提升,对各种能源特别是石油、天然气的需求也越来越大,伴随而来H2S的腐蚀问题也越来越多的引起人们的重视。因此本文主要研究了MDEA对碳钢在含H2S环境下腐蚀行为的影响。

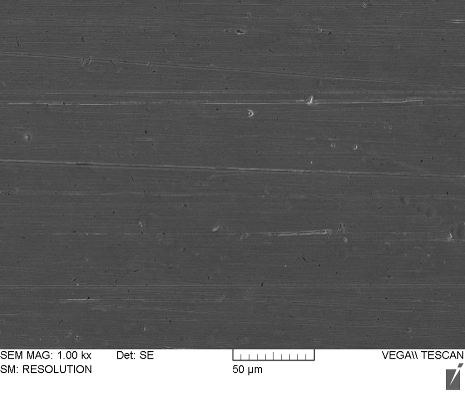

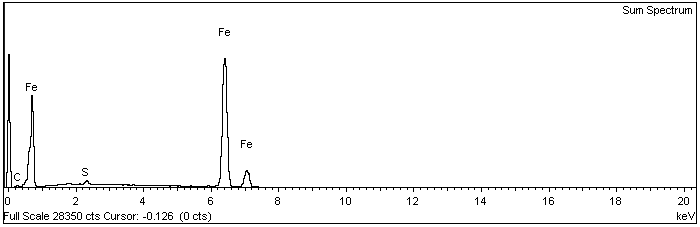

采用腐蚀失重法、慢应变速率拉伸实验法、电化学测试、裂纹金相、扫描电镜(SEM)形貌分析和 X射线衍射(XRD)物相分析,研究了不同浓度MDEA对碳钢在饱和H2S环境中缓蚀性能的影响。主要研究结果如下:

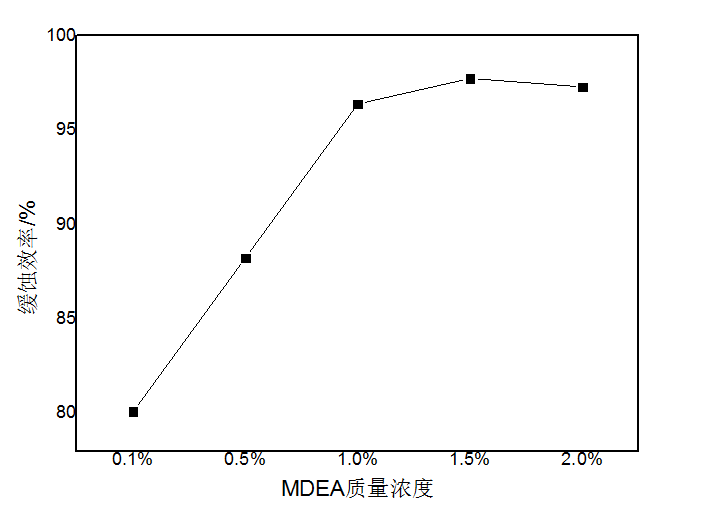

(1)随着饱和H2S溶液中MDEA浓度的不断增加,其对碳钢均匀腐蚀的缓蚀效率先快速增大,然后趋于平缓。当缓蚀剂的浓度大于1%,其缓蚀效率基本恒定在97%左右;(2)饱和H2S溶液中MDEA的浓度低于3%时,其对碳钢应力腐蚀的缓蚀效率较低,浓度达到3%~4.5%时,对碳钢耐应力腐蚀缓蚀效率快速增加,超过6%时,耐应力腐蚀的缓蚀效率增加缓慢,当腐蚀介质中MDEA的浓度为7%时,耐应力腐蚀的缓蚀效率为81.2%。(3)随着饱和H2S溶液中MDEA浓度的不断增加,腐蚀电流密度不断降低,同时碳钢在介质中阳极极化曲线的击穿电位Eb值与碳钢在腐蚀介质中的SSRT性能变化趋势相似。

关键词: 缓蚀剂 MDEA 碳钢 应力腐蚀 硫化氢

Corrosion inhibition performance of MDEA on carbon steel in the environment containing hydrogen sulfide

Abstract

With the rapid increase of China's science and technology and the speed of the social development,For all kinds of energy especially the petroleum and the natural gas is also growing demand, and more and more people pay attention to H2S with corrosion problems.This paper mainly investigated the effect of MDEA on Corrosion Behavior of carbon steel in H2S environment.

By corrosion weight loss method, electrochemical test,crack metallography, SSRT,scanning electron microscope (SEM) and x-ray diffraction phase analysis (XRD), studied the effects of different concentrations of MDEA on carbon steel corrosion in H2S saturated environment. The main research results are as follows:

- With the increase of the concentration of MDEA in saturated H2S solution, the inhibition efficiency of the corrosion of carbon steel increases fast at first and then tends to be gentle. When the concentration of inhibitor is more than 1%, the inhibition efficiency is almost constant at around 97%. (2)When the concentration less than 3%, The inhibition efficiency is low. there are mutations in inhibition efficiency on steel of stress corrosion when the concentration of corrosive media MDEA is 3%-4.5%. When the concentration more than 6%, the inhibition efficiency on steel of resistance stress corrosion increases slowly, When the concentration of corrosive media MDEA is 7%, inhibition efficiency of resistance to stress corrosion increased to 81.2%. (3)With the increase of the concentration of MDEA in saturated H2S solution, the corrosion current density decreases, and the breakdown potential Eb of anodic polarization curves of carbon steel in corrosive medium is similar to that of carbon steel in corrosive environment with the change of SSRT performance.

KEYWORDS: Corrosion inhibitor; MDEA; Carbon steel; Stress corrosion; Hydrogen sulfide

目录

摘要 I

Abstract II

第一章 绪论 1

1.1 引言 1

1.2 硫化氢腐蚀 1

1.2.1 硫化物腐蚀机理 1

1.2.2 应力腐蚀的产生机理 2

1.2.3硫化氢应力腐蚀开裂 3

1.2.4 硫化氢应力腐蚀的影响因素 5

1.3.5 应力腐蚀开裂测试方法 6

1.3 MDEA概述 7

1.3.1 缓蚀剂简介 7

1.3.2 醇胺法脱硫 7

1.3.3甲基二乙醇胺(MDEA)简介 7

1.4 论文的研究目的及意义 8

第二章 实验 9

2.1实验仪器及设备 9

2.2 实验材料及化学试剂 9

2.2.1 实验材料 9

2.2.2 实验试剂 10

2.3 实验方法 11

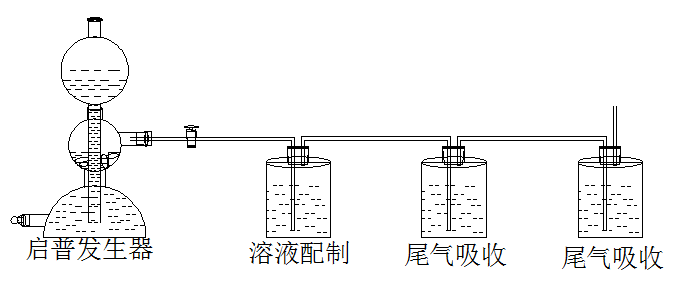

2.3.1 腐蚀介质的配制 11

2.3.2 腐蚀失重法 11

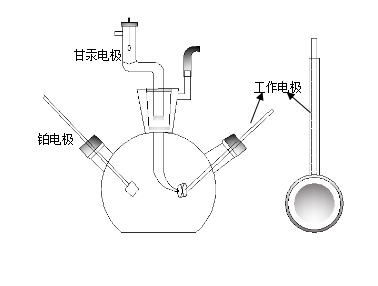

2.3.3 腐蚀电化学测试 12

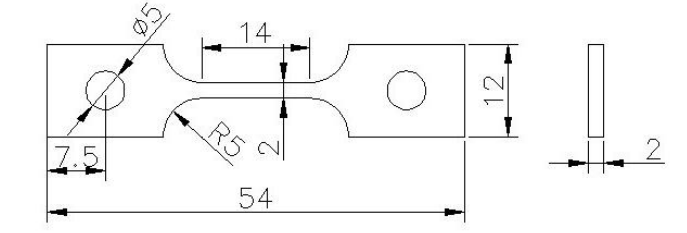

2.3.4 慢应变速率拉伸实验 13

2.3.5 腐蚀产物形貌和断口形貌分析 16

第三章 结果与讨论 17

3.1失重法实验 17

3.1.1失重法腐蚀速率 17

3.1.2腐蚀产物分析 17

3.2慢应变速率拉伸实验 18

3.3慢应变速率拉伸实验试样形貌分析 22

3.4腐蚀电化学测试 23

3.5断裂试样断口形貌分析 25

第四章 结论 29

参考文献 31

致谢 34

- 绪论

1.1 引言

随着科技与社会发展速度的快速提升,石油化工行业作为经济与科技发展的前提和基础,其重要性已被全世界所广泛认可,而伴随而来的腐蚀问题也越来越多的引起人们的重视。硫化氢会导致材料产生氢鼓泡、氢致开裂、应力腐蚀开裂等腐蚀问题,其中因硫化氢导致的应力腐蚀开裂最为危险,而硫化氢对碳钢带来的腐蚀最为严重,因此对硫化氢的应力腐蚀开裂的研究尤为重要。

碳钢用于制造船体、油井或矿井架、高压容器、输送管道等相关设备,并在钢的总产量中占90%。具有以下特点:(1)价格低廉。(2)工艺性能(如焊接性和冷成形性)优良。(3)足够的强度和韧度。因此将碳钢Q235作为此次研究的基体材料[8]。

相关图片展示:

您可能感兴趣的文章

- 元素对Ti-xAl-yMo-zV和Ti-xAl-yMo-zCr β-Ti合金应变速 率敏感性的影响外文翻译资料

- 复合工艺提高先进钠离子电池的电位窗口外文翻译资料

- 氧化还原催化辅助下的高稳定钒氧化还原流电池外文翻译资料

- 用于高压可伸缩储能的电解锌锰电池外文翻译资料

- 表面活性剂改性疏水性Cu2O量子点作为高效钙钛矿太阳能电池顶部空穴传输材料外文翻译资料

- Nb 和 Ni 共掺杂 Mg(0001)氢解离扩散的理论研究:外文翻译资料

- 低温固相法制备锂离子电池正极材料LiFeSO4F毕业论文

- 锂空气电池新型正极催化剂Gd2Zr2O7的制备与性能研究毕业论文

- 酸类添加剂对beta”-Al2O3电泳沉积成型法的影响毕业论文

- CuZr非晶合金中短程有序结构及其与玻璃形成能力的关系研究毕业论文