湖北新农村住宅模块化框式混凝土剪力墙结构设计毕业论文

2020-02-17 01:18:36

摘 要

我国正在大力推广环保无污染的建设发展战略。模块化框式混凝土剪力墙结构是一种全螺栓连接的装配式结构。它由夹着发泡混凝土的预制混凝土板和螺栓组成,主体结构的墙板和楼板自重轻、构件连接安装简单、施工周期短且方便、没有湿作业、保温性能良好及综合成本低,还减少了环境污染。

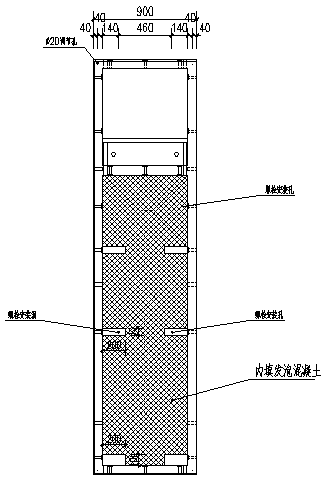

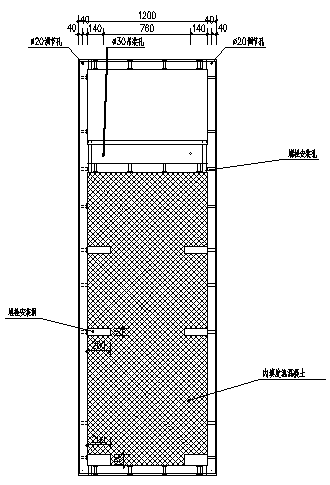

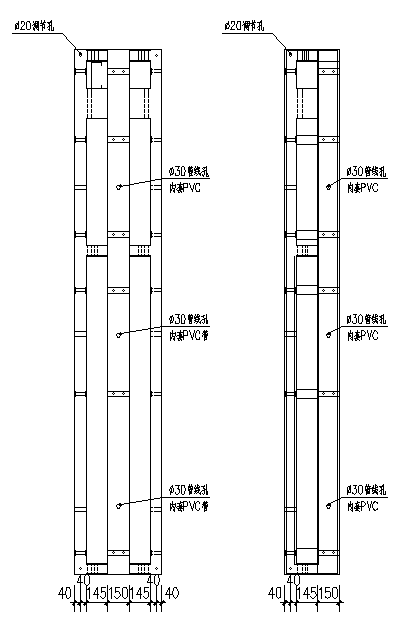

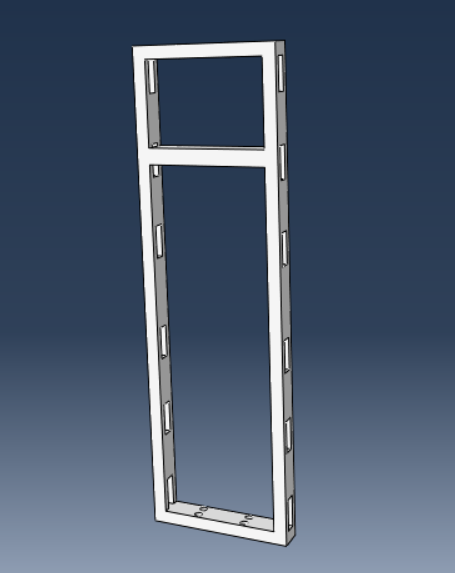

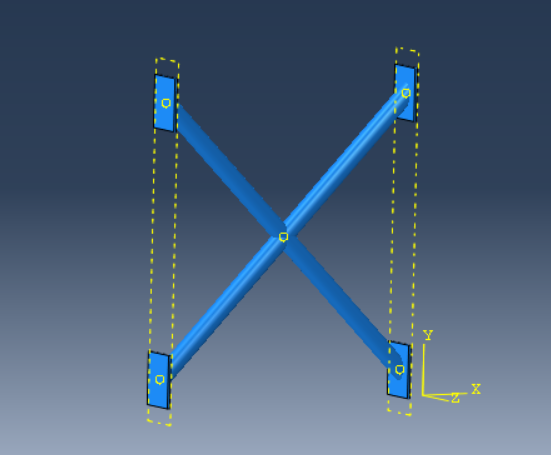

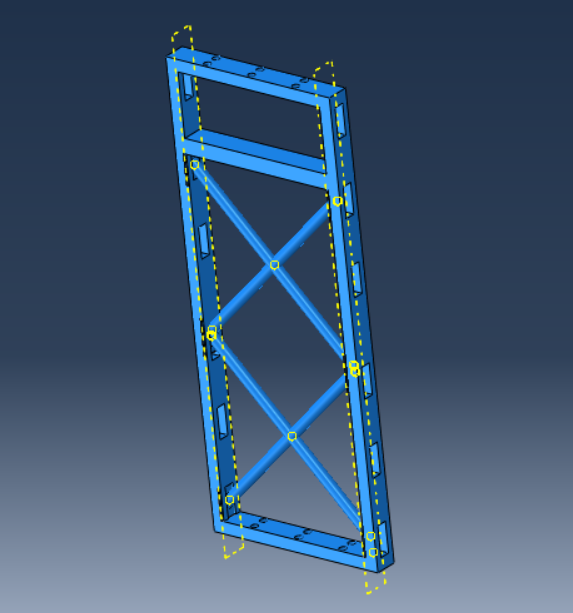

本文研究的是模块化框式混凝土剪力墙结构,以一栋建筑面积约150m2的两层农村住宅为载体,研究墙板在水平和竖向荷载下的承载能力。墙体由预制混凝土模块化直墙板和转角柱组成,墙板宽度为 300mm 的模数,厚度 120mm,相互之间采用螺栓连接。其中框式直墙板由预制混凝土外框和上端横梁构成,框内空当填充轻质混凝土保温材料,即发泡混凝土,上端横梁上放置C型钢梁和预制楼板。模块化转角柱则包括十字形、T型和L型三种。本文以宽度分别为900mm和1200mm,高度为3m的标准预制混凝土板位研究对象,对其进行竖向和水平荷载的承载力试验。通过ABAQUS软件建立墙板的有限元模型,研究墙板在荷载作用下的力学性能,将建筑传递的荷载施加到墙板上,看其应力应变是否达到极限值。分析后得到楼板上放置H型钢梁的数量以及型号,下端墙板中设置的斜向支撑的数量和位置。看这种墙板在实际工程中是否能够推广使用。

通过对模块化框式混凝土剪力墙结构的竖向和水平承载力的有限元分析,可以为该体系的推广作为参考。

关键词:装配式 模块化预制混凝土 承载力试验

Abstract

Our country is vigorously promoting the construction and development strategy of environmental protection and pollution-free. Modular frame concrete shear wall structure is a kind of assembled structure with full bolt connection. It consists of prefabricated concrete slabs and bolts with foamed concrete. The wall slabs and floor slabs of the main structure have the advantages of light weight, simple on-site connection and installation of components, short construction period, non-wet operation, good thermal insulation performance and low comprehensive cost, and also reduce environmental pollution.

In this paper, the modular frame concrete shear wall structure is studied. Taking a two-storey rural residential building with an area of 150 m2 as the carrier, the bearing capacity of the wallboard under horizontal and vertical loads is studied. The wall is composed of prefabricated concrete modular straight wall panels and corner panels. The width of the wall panels is 300 mm modular and the thickness is 120 mm. The bolts are used to connect each other. The frame-type straight wall slab is composed of prefabricated concrete outer frame and upper cross beam. When the frame is empty, it is filled with light concrete insulation material, i.e. foamed concrete. C-shaped steel beam and floor slab are placed on the upper cross beam.Modular corner panels include three types: cross, T and L, which are similar to vertical wall panels. In this paper, the vertical and horizontal load bearing capacity of standard prefabricated concrete slabs with width of 900 m m and height of 1200 m m are tested. The finite element model of wall slab is established by ABAQUS software. The generation of cracks and seismic performance of wall slab under load are studied. The load transferred by building is applied to the wall slab to see whether the stress and strain reach the limit value. After analysis, the number and type of H-shaped steel beams on the floor and the number and position of oblique braces in the lower wall panels are obtained. Observe whether this kind of wallboard can be popularized in practical engineering.Through the finite element analysis of the vertical and horizontal bearing capacity of the modular frame concrete shear wall structure, it can be used as a reference for the popularization of the system.

Key words: loading capacity test of modular prefabricated concrete;Modular precast concret

目 录

中文摘要......................................................................................................................Ⅰ

Abstract......................................................................................................................Ⅱ

- 概述.................................................................................................................1

1.1 引言................................................................................................................1

1.2 国外研究现状................................................................................................2

1.3 国内研究现状................................................................................................3

1.4 本文研究内容................................................................................................5

- 模块化框式混凝土剪力墙结构的介绍.........................................................7

2.1 模块化装配式混凝土剪力墙结构(BMFW)................................................7

2.1.1 传统装配式结构.....................................................................................7

2.1.2 新型螺栓连接装配式结构.....................................................................7

2.2 墙板介绍........................................................................................................9

2.3 楼板介绍.......................................................................................................12

2.4 转角柱介绍...................................................................................................12

2.5 研究步骤.......................................................................................................15

- 模块化框式混凝土剪力墙结构的有限元建模方法....................................17

3.1 有限元方法简介...........................................................................................17

3.2 有限元分析步骤...........................................................................................17

3.3 几何模型的建立...........................................................................................18

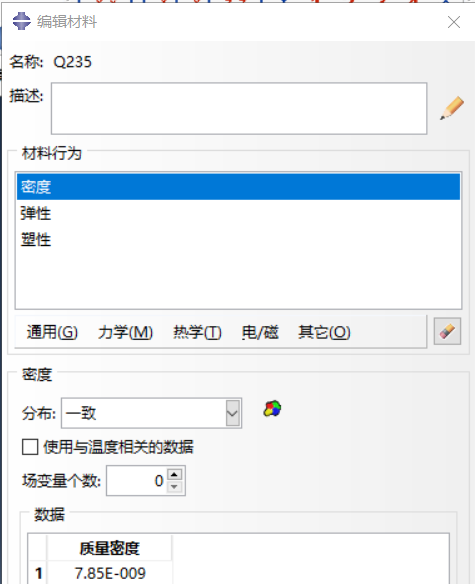

3.4 材料本构模型...............................................................................................22

3.5 网格的划分...................................................................................................22

3.6 边界条件及相互作用...................................................................................24

- 模块化框式混凝土剪力墙结构的工程实例................................................26

4.1 工程概况.......................................................................................................26

4.2 荷载统计.......................................................................................................41

4.2.1 恒荷载统计............................................................................................41

4.2.2 活荷载统计............................................................................................42

4.3 荷载传递.......................................................................................................43

4.3.1 屋面板计算............................................................................................43

4.3.2 钢梁计算................................................................................................44

4.3.3 墙板计算................................................................................................44

4.3.4 集中风荷载标准值计算........................................................................45

4.3.5 地震荷载标准值计算............................................................................48

4.4 有限元结果分析...........................................................................................50

4.5 装配式预制墙板有限元分析和规范计算结果对比...................................57

第五章 结论和展望....................................................................................................58

5.1 结论...............................................................................................................58

5.2 展望...............................................................................................................59

参考文献......................................................................................................................60

致谢..............................................................................................................................62

第一章 概述

- 引言

我国近几年来经济发展迅速,城市规模不断扩大,人们对住宅的需求也在不断提高。国民经济中,建筑是主要的部分。所以我们必须研究出更好的居民住宅来解决住宅紧张的问题。传统的住宅建造方式表现的问题主要有质量差,成本高,工期长,环境污染严重。与科学发展观和可持续发展的战略要求不符。所以,我们要研究一种生产率高,成本低,质量有保证而且对环境没有污染的住宅。

日本在1968年提出“住宅产业化”,指用工业化生产的方式来建造住宅,以提高住宅生产的劳动生产率,提高住宅的整体质量,降低成本,减少了环境污染。是机械化程度不高和粗放式生产的生产方式升级换代的必然要求。我国目前主要以现浇混凝土结构为主,大部分为湿作业,装配式建筑的建筑功能和物理性能存在很多不足,除了装配式单层工业厂房以外,其他装配式结构应用极少。模块化的建筑体系没有形成,施工管理专业化程度不够,建筑产品的尺寸、性能标准化、通用性差。随着建筑产业化的不断推进,体力劳动将逐渐减少,取而代之的将是机械工序,对人们的技术要求也将提高,不再停留在体力劳动的阶段。这是时代发展的必然趋势。建筑产业化讲究绿色发展,通过技术创新对建筑产业升级,以信息化的手段管理,满足住宅产业化的要求,使建筑生产的全过程形成一个完整的产业系统。实现传统生产方式向现代化转变,进而提高经济水平。

我国传统的建筑结构形式为混凝土结构,分为现浇式和预制装配式。上世纪90年代末,由于混凝土输送泵、竹胶板等生产设备的广泛使用,和国家标准对建筑整体性的要求,大部分趋于现浇式混凝土结构。但现浇式混凝土结构有许多不足:

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: