1.钢筋混凝土的基本概念和特征外文翻译资料

2023-08-25 11:16:56

1. BASIC CONCERPTS AND CHARACERACTERISTICS OF REINFORCED CONCRETE

Plain concrete is formed from hardened mixture of cement, water , fine aggregate , coarse aggregate (crushed stone or gravel ) , air and often other admixtures . The plastic mix is placed and consolidated in the formwork, then cured to accelerate of the chemical hydration of hen cement mix and results in a hardened concrete. It is generally known that concrete has high compressive strength and low resistance to tension. Its tensile strength is approximately one-tenth of its compressive strength. Consequently, tensile reinforcement in the tension zone has to be provided to supplement the tensile strength of the reinforced concrete section.

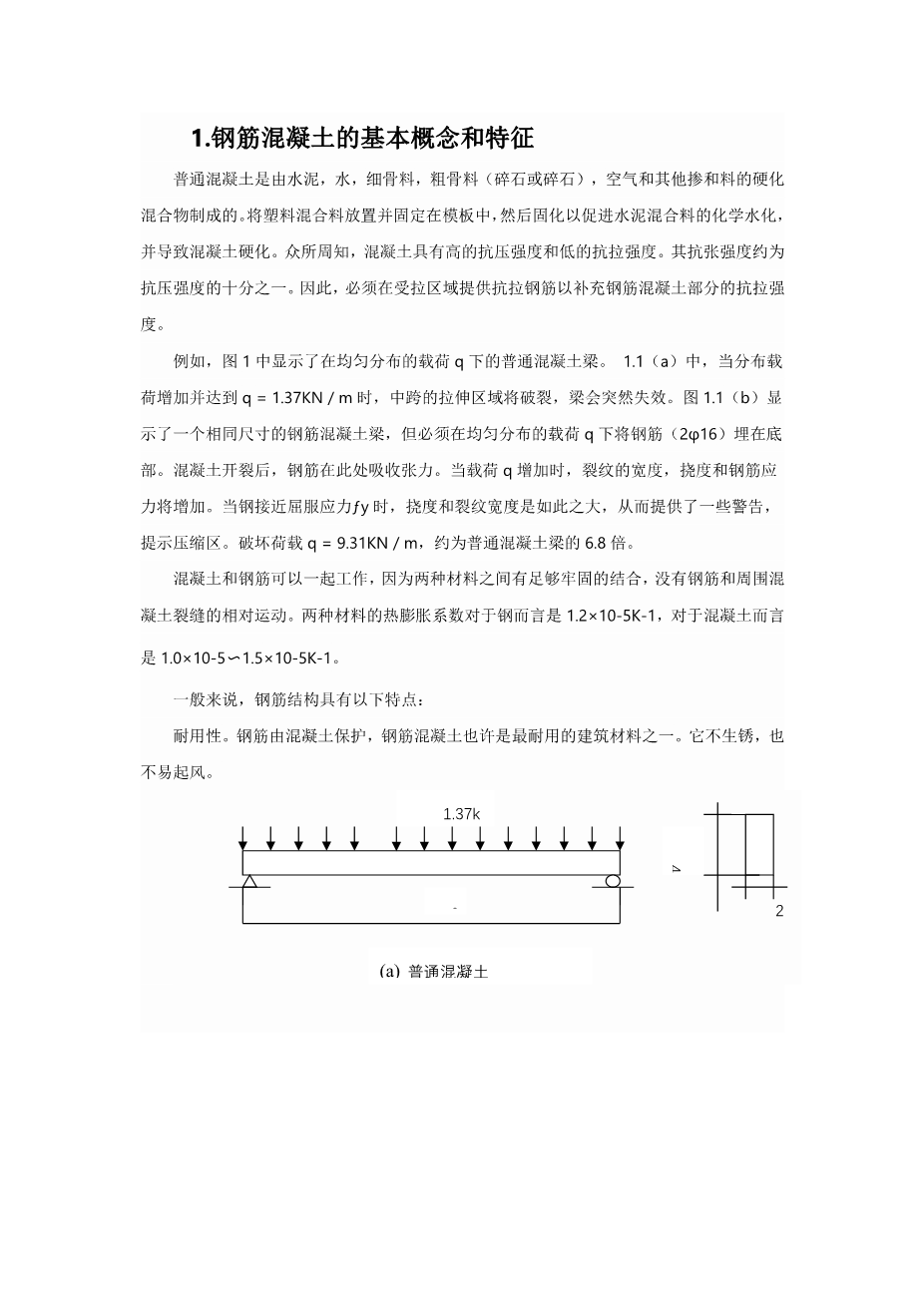

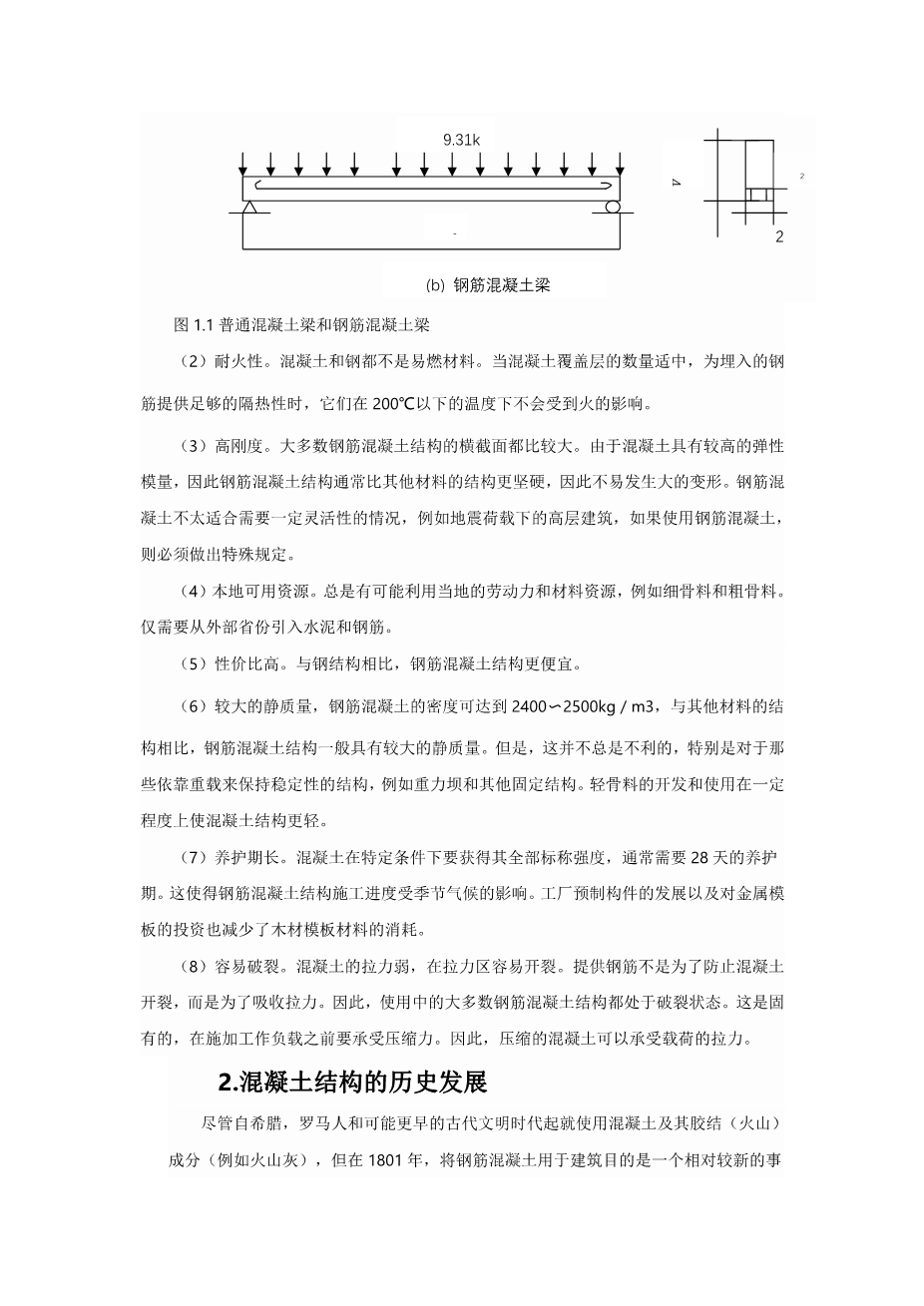

For example, a plain concrete beam under a uniformly distributed load q is shown in Fig . 1.1(a), when the distributed load increases and reaches a value q=1.37KN/m , the tensile region at the mid-span will be cracked and the beam will fail suddenly . A reinforced concrete beam if the same size but has to steel reinforcing bars (2phi;16) embedded at the bottom under a uniformly distributed load q is shown in Fig.1.1(b). The reinforcing bars take up the tension there after the concrete is cracked. When the load q is increased, the width of the cracks, the deflection and the stress of steel bars will increase . When the steel approaches the yielding stress fnof;y , the deflection and the cracked width are so large offering some warning that the compression zone . The failure load q=9.31KN/m, is approximately 6.8 times that for the plain concrete beam.

Concrete and reinforcement can work together because there is a sufficiently strong bond between the two materials, there are no relative movements of the bars and the surrounding concrete cracking. The thermal expansion coefficients of the two materials are 1.2times;10-5K-1 for steel and 1.0times;10-5~1.5times;10-5K-1 for concrete .

Generally speaking, reinforced structure possess following features :

Durability .With the reinforcing steel protected by the concrete , reinforced concrete

1.37kn/m

6m

200

400

(a)plain concrete beam

9.31kn/m

6m

200

400

(b)Reinfoced concrete beam

2phi;16

Fig.1.1Plain concrete beam and reinforced concrete beam

Is perhaps one of the most durable materials for construction .It does not rot rust , and is not vulnerable to efflorescence .

(2)Fire resistance .Both concrete an steel are not inflammable materials .They would not be affected by fire below the temperature of 200℃ when there is a moderate amount of concrete cover giving sufficient thermal insulation to the embedded reinforcement bars.

(3)High stiffness .Most reinforced concrete structures have comparatively large cross sections .As concrete has high modulus of elasticity, reinforced concrete structures are usually stiffer than structures of other materials, thus they are less prone to large deformations, This property also makes the reinforced concrete less adaptable to situations requiring certain flexibility, such as high-rise buildings under seismic load, and particular provisions have to be made if reinforced concrete is used.

(4)Locally available resources. It is always possible to make use of the local resources of labour and materials such as fine and coarse aggregates. Only cement and reinforcement need to be brought in from outside provinces.

(5)Cost effective. Comparing with steel structures, reinforced concrete structures are cheaper.

(6)Large dead mass, The density of reinforced concrete may reach 2400~2500kg/m3.Compare with structures of other materials, reinforced concrete structures generally have a heavy dead mass. However, this may be not always disadvantageous, particularly for those structures which rely on heavy dead weight to maintain stability, such as gravity dam and other retaining structure. The development and use of light weight aggregate have to a certain extent make concrete structure lighter.

(7)Long curing period.. It normally takes a curing period of 28 day under specified conditions for concrete to acquire its full nominal strength. This makes the progress of reinforced concrete structure construction subject to seasonal climate. The development of factory prefabricated members and investment in metal formwork also reduce the consumption of timber formwork materials.

(8)Easily cracked. Concrete is weak in tension and is easily cracked in the tension zone. Reinforcing bars are provided not to prevent the concrete from cracking but to take up the tensile force. So most of the reinforced concrete structure in service is behaving in a cracked state. This is an inherent is subjected to a compressive force before working load is applied. Thus the compressed concrete can take up some tension from the load.

2. HISTOEICAL DEVELPPMENT OF CONCRETE STRUCTURE

Although concrete and its cementitious(volcanic) constituents, such as pozzolanic ash, have been used since the days of Greek, the Romans, and possibly earlier ancient civilization, the use of reinforced concrete for construction purpose is a relatively recent event, In 1801, F. Concrete published his statement of principles of construction, recognizing the weakness if concrete in tension, The beginning of reinforced concrete is generally attributed to Frenchman J. L. Lambot, who in 1850 constructed, for the first time, a small boat with concrete for exhibition in the 1855 Worldrsquo;s Fair in Paris. In England, W. B. Wilkinson registered a patent for reinforced concrete l=floor slab in 1854.J.Monier, a French gardener used metal frames as reinforcement to make garden plant containers in 1867. Before 1870, Monier had taken a series of patents to make reinforced concrete pipes, slabs, and arches. But Monier had no knowledge of the working principle of this new material, he placed the reinforcement at the mid-depth

剩余内容已隐藏,支付完成后下载完整资料

英语译文共 5 页,剩余内容已隐藏,支付完成后下载完整资料

资料编号:[607820],资料为PDF文档或Word文档,PDF文档可免费转换为Word