700kW发电机组轴系扭转振动计算及分析外文翻译资料

2021-12-16 23:16:15

Stowage Planning

Overview

Autoship Systems Corporation Stowage Planning Systems do far more than just model how cargo will fit in your vessels: they handle any cargo you transport, all voyages, all ports, and all your vessels; they are global information systems that permit both long-range and immediate planning; they incorporate your existing bookings database, and bring shipping operations fully into your supply chain management system.

Central to our stowage planning software is our concept of the electronic stowage plan, or Stowage Plan File. The stowage plan file is the repository for all information associated with your stowage simulation for a particular vessel and voyage. The stowage plan Information stored includes the graphical representation, the booking list being used, the location and status of cargo within the vessel, and the corresponding hydrostatic condition of the vessel. These stowage plan files also provide the key to seamless data transfer. All Autoship stowage planning systems include the latest version of our

comprehensive hydrostatics analysis engine - Autoloadreg;.

Our basic system is tailored to each shipping line, cargo type, and vessel according to your needs. However, the general planning requirements imposed by different cargo types allow us to start from these basic planning solution modules:

Ro-Ro

Use the graphical stowage tools in our Ro-Ro stowage module to stow, reposition, or remove all cargo on all decks. The viewing tools are very flexible, and allow you to decide on the level of detail to be shown. Loading, repositioning, and removal results at any selected port are automatically predicted for all future ports in the voyage.

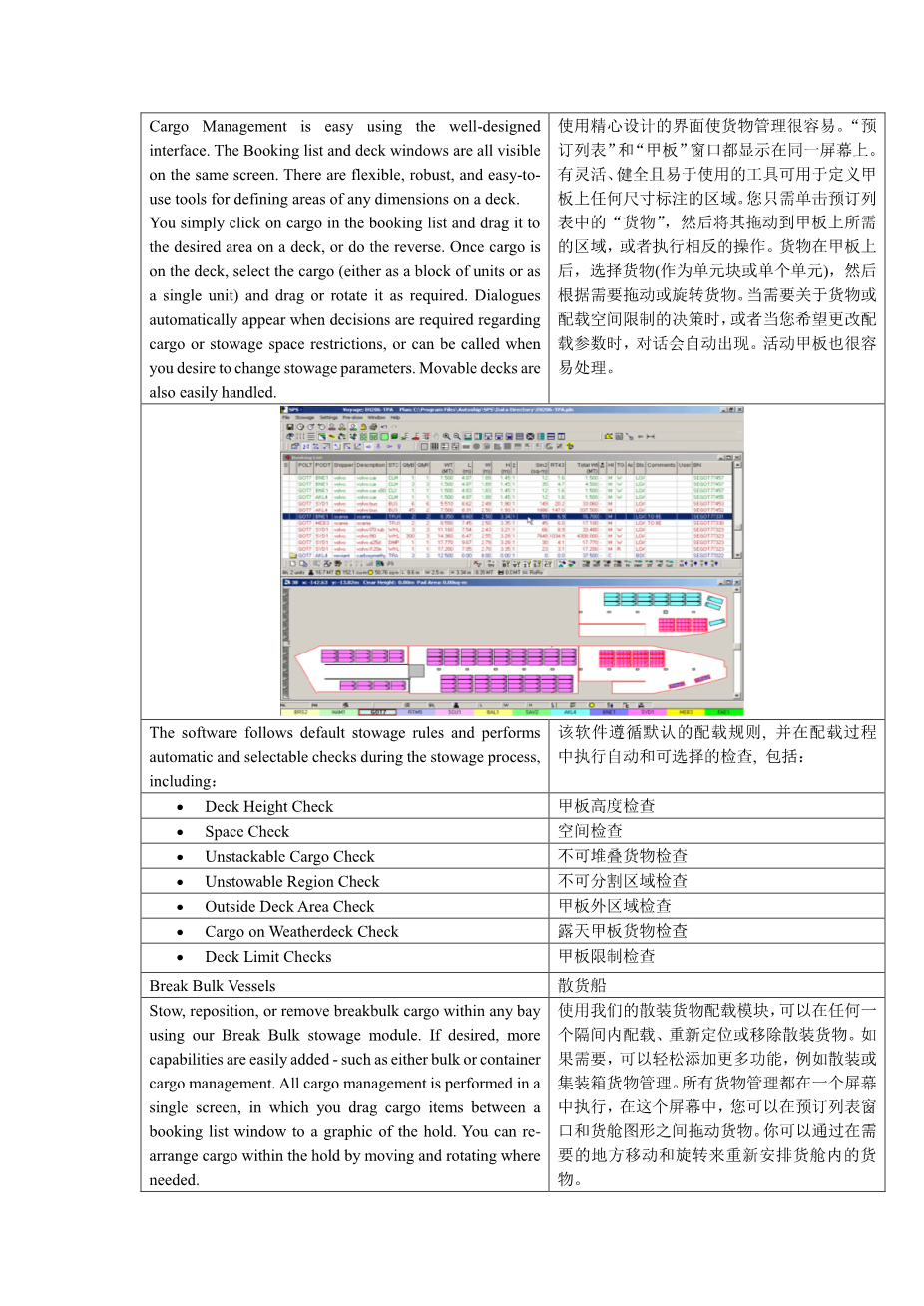

Cargo Management is easy using the well-designed interface. The Booking list and deck windows are all visible on the same screen. There are flexible, robust, and easy-to-use tools for defining areas of any dimensions on a deck. You simply click on cargo in the booking list and drag it to the desired area on a deck, or do the reverse. Once cargo is on the deck, select the cargo (either as a block of units or as a single unit) and drag or rotate it as required. Dialogues automatically appear when decisions are required regarding cargo or stowage space restrictions, or can be called when you desire to change stowage parameters. Movable decks are also easily handled.

The software follows default stowage rules and performs automatic and selectable checks during the stowage process, including:

- Deck Height Check

- Space Check

- Unstackable Cargo Check

- Unstowable Region Check

- Outside Deck Area Check

- Cargo on Weatherdeck Check

- Deck Limit Checks

Break Bulk Vessels

Stow, reposition, or remove breakbulk cargo within any bay using our Break Bulk stowage module. If desired, more capabilities are easily added - such as either bulk or container cargo management. All cargo management is performed in a single screen, in which you drag cargo items between a booking list window to a graphic of the hold. You can re-arrange cargo within the hold by moving and rotating where needed.

With our flexible viewing tools you can zoom in on specific cargo or zoom out to see any portion of the hold. The results of loading, repositioning, or removal at any selected port are automatically predicted for all future ports in the voyage.

Dialogues automatically appear when stowage management decisions are required, or when you wish to change stowage parameters or gain additional information. The software follows default stowage rules and performs automatic and selectable checks during the stowage process.

All Autoship stowage planning systems include the latest version of our

comprehensive hydrostatics analysis engine - Autoloadreg;

Container Vessels

Our container stowage planning module handles both covered deck and weather-deck stowage. Containers can be loaded, repositioned, and removed at any selected port, with the results of these changes automatically predicted for all future ports in the voyage. Views are easily switched from bay to bay and from port to port throughout the planned voyage:

Stow Cargo by dragging and dropping single or multiple containers from Booking List to the bay selected in the bayplan window, and let the system automatically choose slots within the bay according to user-controlled criteria. Or, you can stow containers in specific slots in a bay, using well-designed dialogues. Other dialogues will appear when stowage management decisions are required, or you can call them when you wish to change stowage parameters. Reposition or remove containers using simple drag-and-drop features. Out of Gauge Cargo is also facilitated.

The software follows default stowage rules and performs automatic and selectable checks during the stowage process. Some of these default stowage rules can be editable.

Usually, the software stores multiple containers using the same method: it first fills the center bottom cell, then the cell immediately to the starboard of the centre cell, then the immediate port cell, and continues to alternate outwards in this starboard-port pattern until the tier is filled. If there is no centre cell, the

英语原文共 24 页

资料编号:[4784]