TC4-0.1Fe合金的悬浮熔炼及热压缩对其组织和性能的影响毕业论文

2020-07-06 18:15:57

摘 要

ABSTRACT 2

第一章 绪论 3

1.1钛合金的概述 3

1.1.1钛合金的分类 3

1.1.2 Ti-6Al-4V钛合金的特征与优势 3

1.1.3 Ti-6Al-4V钛合金的应用 3

1.2 合金元素的添加对Ti-6Al-4V钛合金的影响 4

1.2.1 常见的合金添加元素 4

1.2.2 合金元素的添加对显微组织和力学性能的影响 4

1.3 热压缩对TC4合金组织和性能的影响 4

1.3.1 显微组织的影响 4

1.3.2 力学性能的影响 5

1.4 本课题的研究目的和意义 6

第二章 实验方案 7

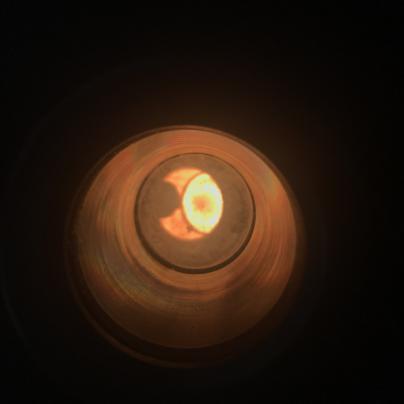

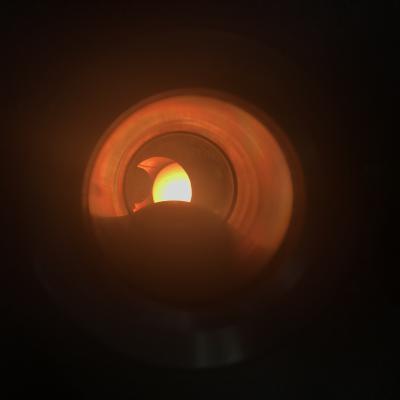

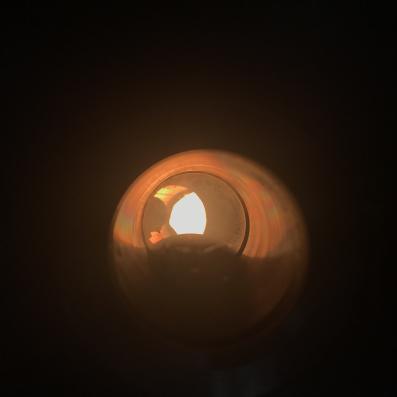

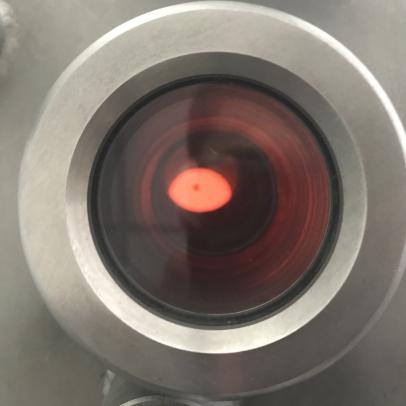

2.1 悬浮熔炼 7

2.1.1 悬浮熔炼的优势 7

2.1.2 确定配料 7

2.1.3 熔炼过程 7

2.2 热压缩试验 11

2.3分析方法 12

2.3.1 分析试样制备 12

2.3.2 金相分析 15

2.3.3 XRD物相分析 16

2.3.4维氏硬度测试 16

2.4 本章小结 17

第三章 实验结果分析与讨论 19

3.1金相分析 19

3.1.1显微组织图像分析 19

3.1.2 金相成分分析 22

3.2 XRD物相分析 22

3.3 热变形数据分析 25

3.4 合金硬度分析 32

3.5 本章小结 33

第四章 结论 34

参考文献 35

致谢 37

TC4-0.1Fe合金的悬浮熔炼和热压缩对其组织和性能的影响

摘要

Ti-6Al-4V合金由于综合力学性能优异被广泛使用,但其却有着热加工性能低、成本高的缺点。而在合金中加入Fe元素可以对其的高温加工性能的改变有一定的作用。本文研究了悬浮熔炼和热压缩对Ti-6Al-4V-0.1Fe合金组织和性能的影响。首先使用悬浮熔炼的方法熔炼出TC4-0.1Fe合金,而后采用Gleeble3800热模拟压缩试验机研究了合金在变形温度为800℃,900℃,1000℃和压缩速率为0.01s-1及1s-1下的热变形行为。采用金相显微镜,XRD物相分析等手段研究了它的微观组织。对于其力学性能方面的研究则是测量了合金的维氏硬度。研究的结果如下所示:

- 变形温度和变形速率对Ti-6Al-4V-0.1Fe合金的热压缩行为有着重要的影响,在相同的变形温度下,峰值应力随着压缩速率的增大而增大,在800℃下当峰值应力升至1s-1时,峰值应力可以达到283MPa。在相同的压缩速率下,峰值应力随着变形温度的增大而减小,在压缩速率为0.01s-1时,温度上升到1000℃,峰值应力却减少到24MPa。

- 变形温度在800℃和900℃时,金相发生了动态回复,而在1000℃时,金相则发生了动态再结晶现象。

(3)当压缩速率不变时,合金试样的硬度值随着温度的升高而降低,在压缩速率为0.01s-1,硬度值低值319.94。而当变形温度不变时,合金试样的硬度值随着压缩速率的升高而升高。

关键词:钛合金 热变形 悬浮熔炼 微观组织

Effect of Suspension Melting and Hot Compression on Microstructure and Properties of TC4-0.1Fe Alloy

ABSTRACT

Ti-6Al-4V alloy is widely used because of its excellent comprehensive properties, but it has the disadvantage of low hot-working characteristic and high cost. The addition of Fe to alloy can change its high temperature processing performance. The effects of suspension melting and hot compression on the microstructure and properties of Ti-6Al-4V-0.1Fe alloy have been studied. Firstly, TC4-0.1Fe alloy was produced by suspension melting. Then the thermal deformation behavior of the alloy at 800℃、 900℃、1000℃and compression rate of 0.01s-1 and 1s-1 was studied by Gleeble3800 thermal simulation compression test machine. The microstructure was studied by means of metallographic microscope and XRD and The Vickers hardness of the alloy was measured. The results of the study are as follows:

- The hot deformation behavior of Ti-6Al-4V-0.1Fe alloy is very sensitive to the deformation temperature and compression rate. At the same deformation temperature, the peak stress increases with the increase of compression rate. When the peak stress rises to 1s-1 at 800℃, the peak stress can reach 283 MPA. But at the same compression rate, the peak stress decreases with the increase of deformation temperature. When the compression rate is 0.01s-1, the temperature rises to 1000℃ and the peak stress decreases to 24 MPA.

- When the deformation temperature is 800℃and 900℃, the dynamic spheroidization occurs. While the dynamic recrystallization occurred at 1000 ℃.

- When the compression rate is constant, the hardness of the alloy decreases with the increase of temperature.At a compression rate of 0.01s-1 , the hardness value is low value of 319.94. However, when the deformation temperature is constant, the hardness of the alloy increases with the increase of the compression rate.

Keywords: titanium alloy thermal deformation smelting in suspension

Microstructure

绪论

1.1钛合金的概述

相关图片展示: