半导体多晶硅精馏塔腐蚀预防与应急管理研究毕业论文

2020-04-25 19:39:37

摘 要

近年来,随着我国太阳能光伏产业以及电子信息技术的快速发展,对于多晶硅的需求量也在持续高速增长。目前精馏三氯氢硅是多晶硅生产工艺过程中的主要工序,在实际生产的操作中,精馏工序中的精馏塔会受到不同程度、不同方式的腐蚀,从而导致其使用寿命缩短、使用效果不佳,直接影响多晶硅产业的正常运转,造成严重的经济损失。所以在多晶硅生产工艺过程中分析精馏塔的腐蚀问题,选择有效的腐蚀预防与应急管理措施对于减少设备腐蚀情况的发生具有重要的意义。

为了提高多晶硅生产行业的工艺安全性,分析生产工艺中精馏塔的腐蚀情况,分析精馏塔可能发生的危险事故,采取有效地预防与应急管理措施,因此本设计重点分析了多晶硅生产工艺改良西门子法中可能存在的危险、有害因素,生产过程中产生的主要副产物对精馏塔材质的腐蚀影响情况,并针对精馏操作中可能发生的特定事故提出了预防与应急管理措施。

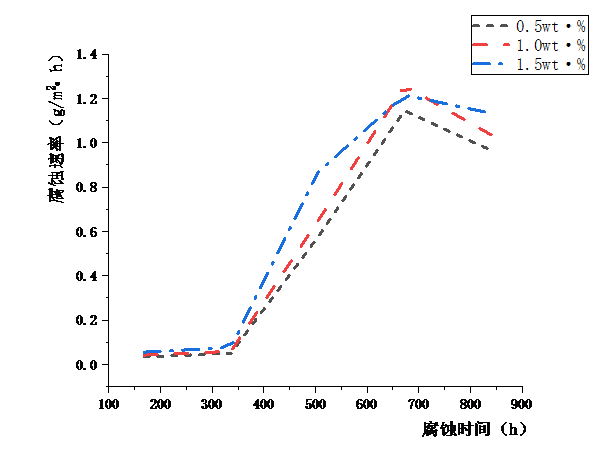

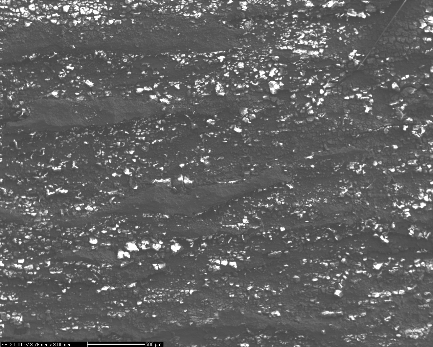

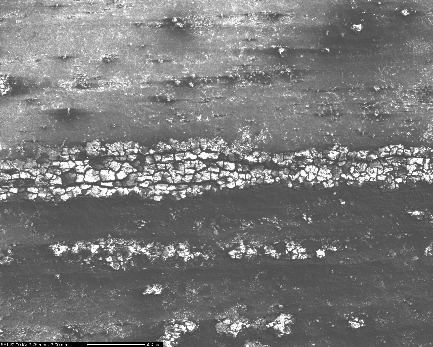

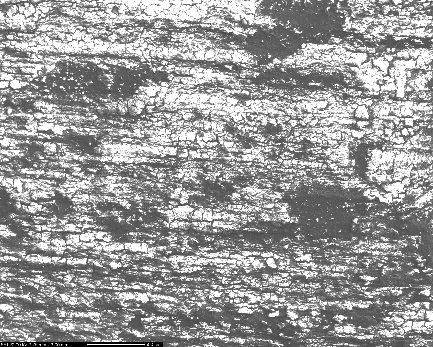

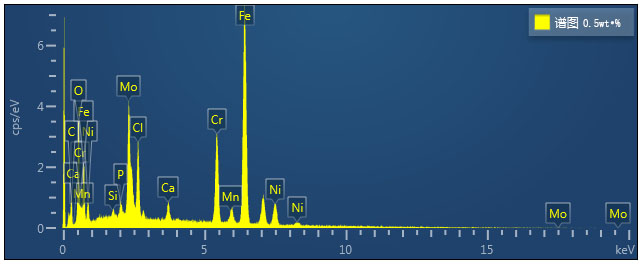

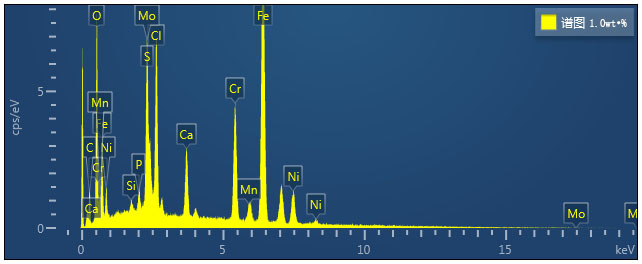

其中利用安全评价方法中的事故树分析法分析精馏塔腐蚀的主要原因,得出导致腐蚀的主要原因为未及时检修精馏塔和反应产生了腐蚀性介质。利用挂片腐蚀实验、扫描电镜实验和X射线衍射实验对316L不锈钢的腐蚀影响因素进行分析,得出在实验条件下腐蚀速率随着时间的增加先上升后下降,且随HCl浓度的增加而加快,设备表面主要存在均匀腐蚀、缝隙腐蚀和孔蚀等,腐蚀产物主要由Cr2O3、Fe2O3、FeOOH等组成。针对精馏操作中精馏塔可能出现的危险事故进行了综合分析,根据事故树分析结果、实验结果和实际情况等对精馏操作中精馏塔可能出现的火灾、爆炸、腐蚀、中毒等事故针对性地制定了预防和应急管理措施。

通过本次设计,对多晶硅生产行业中的主要危险、有害因素有了明确的认识,明确了精馏塔内的主要腐蚀介质对精馏塔的腐蚀影响程度及腐蚀方式,也有了针对精馏塔发生危险事故的应急措施。根据设计的内容能够指导在生产过程中应多注意SiHCl3、SiCl4、HCl等比较危险的因素,对精馏塔设备要进行日常维护保养,及时清理设备残余,防止发生其腐蚀。对于精馏塔可能产生的危险事故有了针对性的处置措施,总体对于多晶硅生产产业安全性的提高有很大的促进作用。

关键词:多晶硅 316L不锈钢 腐蚀预防 应急管理

Research on Corrosion Prevention and Emergency Management of Semiconductor Polycrystalline Distillation Tower

ABSTRACT

In recent years, the solar photovoltaic industry and electronic information technology have developed rapidly in China, and the demand for its main raw material polysilicon has continued to grow rapidly. At present, distillation Trichlorosilane is the main process in polysilicon production process. In the actual production operation, the distillation column in the distillation process will be corroded in different degrees and different ways, resulting in shortening its service life and poor use effect, which directly affects the normal operation of the industry and causes serious economic losses. Therefore, in the polysilicon production process to analyze the corrosion problems of distillation equipment, the selection of effective corrosion prevention and emergency management measures is of great significance to reduce the occurrence of equipment corrosion.

In order to improve the process safety of polysilicon production industry, analyze the corrosion of distillation column in production process, analyze the possible dangerous accidents of distillation column, take preventive and emergency management measures, this design focuses on the analysis of polysilicon production Process Improvement Siemens method may exist dangerous, harmful factors, The main by-products produced by the production process affect the corrosion of the distillation column material, and the emergency prevention and emergency management measures are put forward for the specific accidents that may occur in the distillation operation.

Among them, the main cause of corrosion caused by the rectification tower is analyzed by the accident tree analysis method in the safety evaluation method. The main reason for the corrosion is that the rectification tower is not repaired in time and the reaction produces corrosive medium. The corrosion influencing factors of 316L stainless steel were analyzed by coupon corrosion test, scanning electron microscopy and X-ray diffraction experiments. It was found that the corrosion rate increased first and then decreased with the increase of time under the experimental conditions, and accelerated with the increase of HCl concentration. The surface of the equipment mainly has uniform corrosion, crevice corrosion and pitting corrosion. The corrosion products are mainly composed of Cr2O3, Fe2O3 and FeOOH. A comprehensive analysis of possible dangerous accidents in the rectification column in the rectification operation, according to the results of the accident tree analysis, experimental results and actual conditions, may cause fire, explosion, corrosion, poisoning and other accidents in the rectification column in the rectification operation. Emergency prevention and emergency management measures were formulated in a targeted manner.

Through this design, we have a clear understanding of the main hazards and harmful factors in the polysilicon production industry, and clarify the degree of corrosion and corrosion of the main corrosive medium in the rectification tower on the rectification tower, and also on the rectification tower. Emergency measures for dangerous accidents According to the design content, we should pay more attention to the more dangerous factors such as SiHCl3, SiCl4, HCl, etc. in the production process, and carry out routine maintenance on the distillation column equipment, timely clean up the equipment residues and prevent corrosion. Targeted disposal measures for hazardous accidents that may occur in the distillation column. Overall for the polysilicon production industry safety improvement has a great role in promoting.

Keywords: Polysilicon; 316L stainless steel; Corrosion prevention; Emergency management

目录

摘 要 I

ABSTRACT II

第一章 综述 1

1.1研究背景 1

1.2研究意义 1

1.3研究现状 2

1.4研究不足 4

1.5本章小结 4

第二章 多晶硅简介和工艺流程 5

2.1多晶硅简介 5

2.2多晶硅制作方法及主要生产工艺 5

2.2.1 改良西门子法 5

2.2.2 硅烷法 6

2.2.3 流化床法 6

2.3本章小结 7

第三章 多晶硅工艺过程危险性分析 8

3.1 安全系统工程评价方法简介 8

3.1.1评价方法分类 8

3.1.2评价方法选择过程 8

3.1.3评价方法的比较 8

3.2危险物料及工艺过程危险性分析 10

3.2.1 生产过程中主要危险物料 10

3.2.2工艺过程腐蚀危险性分析 11

3.3本章小结 13

第四章 半导体多晶硅精馏塔腐蚀实验研究 14

4.1 研究内容 14

4.2 实验原理 14

4.2.1挂片实验 14

4.2.2扫描电镜实验 15

4.2.3 X射线衍射实验 15

4.3实验步骤 15

4.3.1 挂片实验 15

4.3.2 扫描电镜实验 16

4.3.3 X射线衍射实验 17

4.4 实验结果分析 18

4.4.1 挂片实验腐蚀速率分析 18

4.4.2 扫描电子显微镜分析 19

4.4.3 X射线衍射分析 21

4.5本章小结 23

第五章 腐蚀事故树分析 24

5.1事故树简介 24

5.2事故树的编制 24

5.3事故树的分析程序 24

5.4腐蚀危险性分析 26

5.4.1均匀腐蚀事故树 26

5.4.2缝隙腐蚀事故树 29

5.5 本章小结 31

第六章 预防措施与应急管理研究 32

6.1 预防措施 32

6.2 应急管理措施 34

6.2.1精馏塔泄漏的火灾、爆炸事故应急措施 34

6.2.2精馏塔泄漏的腐蚀事故应急措施 35

相关图片展示: