某水泥石灰岩矿山700万吨年开采设计及雷管跳段概率分析毕业论文

2020-02-18 00:09:40

摘 要

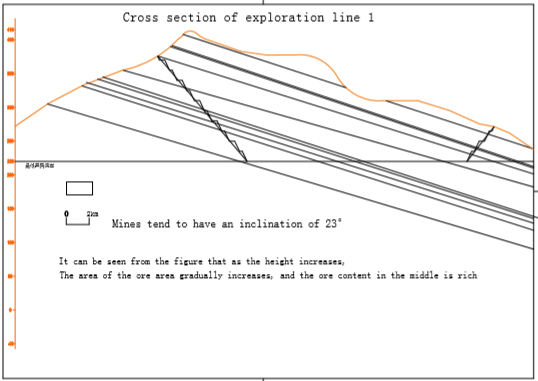

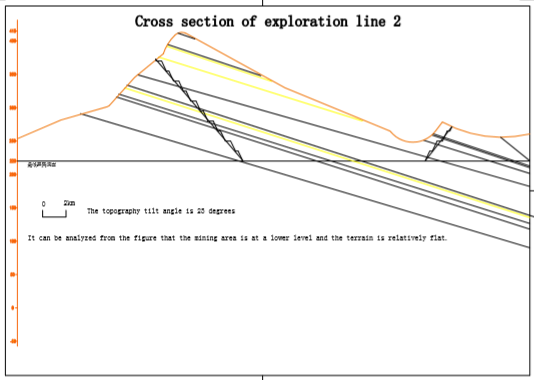

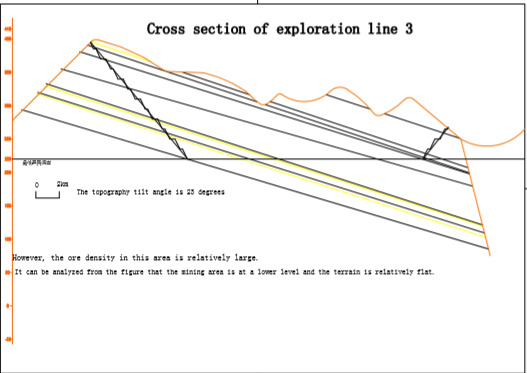

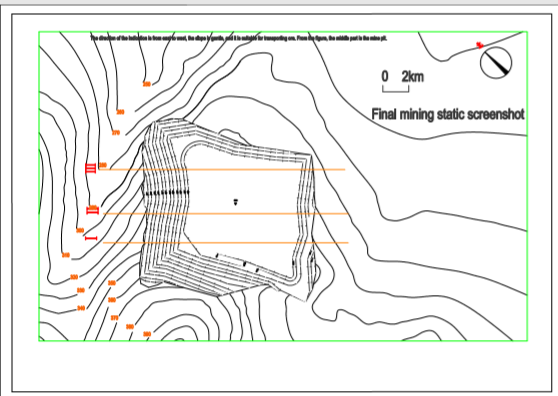

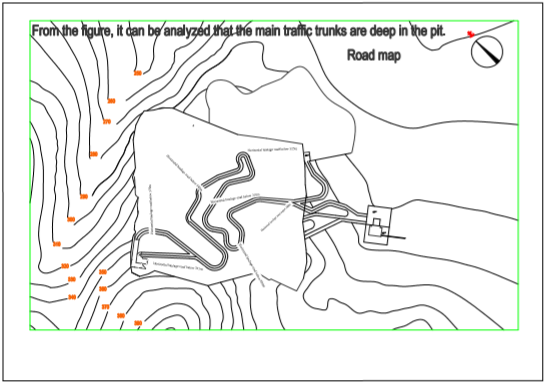

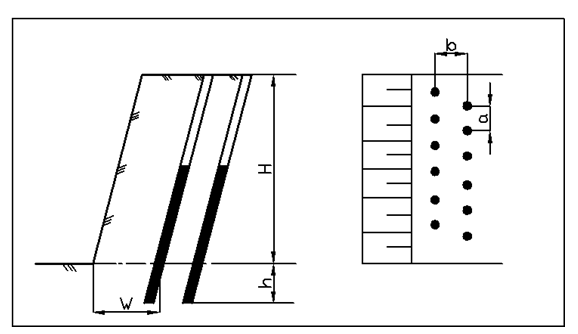

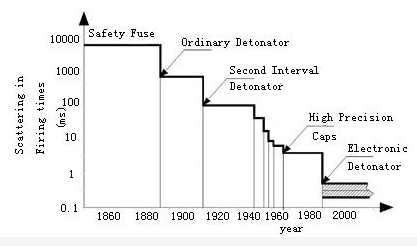

本设计论文以焦作市某水泥灰岩矿区为研究对象,主要针对矿区内的西矿段,按照国家的相关规定和设计规范,搜集相关的资料和数据,根据该矿段所处的地质条件,进行年产量600万吨的开采设计。设计的主要内容包括矿山概况,地质信息,矿山开拓和运输,开采方案确定等方面。同时对露天开采、采矿方法和爆破工作的详细情况进行了探讨。确定了露天矿的合理坡角,确定了开采境界。使用AutoCAD进行工程图的绘制,并确定采矿深度和采矿边界。针对本设计中的研究题目,雷管跳段概率的计算,选取675ms 和 700ms两个延期时间,在分析两个延期时间的离散程度和概率分布的基础上,采用Winzer Index进行跳段概率的计算。并且对比了非电雷管和电子雷管在延期时间离散程度的差异,以及相应的雷管跳段概率的计算结果。结果表明,电子雷管的精度要远高于普通非电雷管,并且相邻延期的跳段概率极低。

关键词:石灰石矿;露天开采设计;雷管跳段概率

ABSTRACT

This design paper takes a cement limestone mining area as the research object, mainly for the western Ore area in the mining area, according to the relevant regulations and design norms of the country. This design collected relevant literature and data, and carried out the design of annual output of 6 million tons, according to the geological conditions of the mine section. The main contents of the design include mine overview, geological information, mine development and transportation, mining scheme determination and so on. At the same time, the details of open-pit mining, mining methods and blasting work are discussed. The reasonable slope angle of open pit mine was determined, and the mining realm was determined. Five drawings have been finished by using AutoCAD including determination of mining depth and mining boundaries.

Aiming at the research topic in this design, the overlapping probability between two adjacent delays was calculated by selecting two delay times of 675ms and 700ms. On the basis of analyzing the dispersion degree and probability distribution of two delays, the Winzer Index was used to calculate the overlapping probability. The difference of the dispersion degree between the non-electric detonator and the electronic detonator in the delay time and the calculation results of the corresponding detonator overlapping probability were also compared. The results showed that the accuracy of the electronic detonator is much higher than that of the ordinary non-electric detonator, and the overlapping probability of the electronic detonators is very low.

Key words: Limestone mine; Open-pit mine design; overlapping probability

Table of Contents

Chapter 1 Introduction to Design 1

1.1 Design Background 1

1.2 Purpose and Significance of Design 1

1.3 The mining area and some requirements 1

1.4 The geographical location and traffic conditions. 2

1.5 Use of Lime Rock 3

Chapter 2 Mine Geology 5

2.1 Strata in Mining Area 5

2.2 Composition, quality, structure, type of ore 9

2.2.1 Chemical composition 9

2.2.2 Ore structure 10

2.2.3 Ore type and grade. 11

2.3 Mining area structure 11

2.3.1 Faults 11

2.3.2 Deposit characteristics 13

2.3.3 Surrounding Rock and Interlayer 15

2.3.4 Karst and filling materials 17

2.4 Engineering Geological Conditions 18

2.4.1 The influence of fissures on the stability of ore beds 18

2.4.2 Stability of intercalated rocks 18

2.4.3 Stability of roof and floor of ore bed 19

2.4.4 Slope stability analysis 19

2.5 Environmental Geology 20

2.5.1 Regional stability 20

2.5.2 Hydrogeology of ore deposits 21

2.6 Estimation of resources 24

Chapter 3 Open-pit mining design 25

3.1 Determination of open-pit mining boundary and depth 25

3.1.1 Open pit boundary 25

3.1.2 The procedure to determine the mining boundary 26

3.1.3 Stope elements 30

3.1.4 Mine annual output service life and working system 30

3.2 Development and transportation 31

3.2.1 Development method selection 31

3.2.2 Development of transport system 32

3.2.3 Mining method 32

3.3 Blasting and loading 34

3.3.1 Blasting work drilling and hole arrangement 34

3.3.2 Blasting parameters 34

3.3.3 Blasting Seismic Safety Distance Checking Calculation 37

3.3.4 Mine infrastructure projects 38

3.3.5 Automobile model selection and mine roads mine car selection 38

Chapter 4 Overlapping Timing Analysis 41

4.1 Introduction 41

4.2 Scatter in firing time 42

4.3 Analysis of overlapping probability 44

4.4 Discussion 46

Chapter 5 Conclusions 48

Acknowledgement 49

Reference 50

Chapter 1 Introduction to Design

1.1 Design Background

This research paper focus points is to design a seven million tons/ cement limestone mine and analysis of overlapping probability between two adjacent detonator delays. This chapter is the brief introduction to the design background of the cement limestone mine in this research.

The following contents are some basic information for this design.

(a) The Cement Limestone Exploration Report of the Mining Area.

(b) Current national and local laws, regulations and standards related to industries.

(c) Specifications and technical provisions for engineering design of cement mines.

Prime purpose of engineering design is to apply scientific knowledge to the solution of technical problems.

1.2 Purpose and Significance of Design

The purpose and significance of the design in this research is to complete a mining design cement limestone mine of 700 million tons/year, and to complete the analysis of the overlapping probability between two adjacent detonators. The detailed design contents are included as follows:

(1) To analyze the general situation of the mining area and the geological features of the deposit.

(2) The reasonable slope angle and the open pit boundary are determined. In this research, there are five drawings by using AutoCAD to determine the mining depth and mining boundary. The information can be tracked in the following section.

(3) Development of mining fields (selection of mining method, equipment type, transportation systems, etc.);

(4) Mining parameters, mining procedures; drawing a base map of plane or section design.

(5) Production capacity of the open pit mine (work system, calculation of ore and rock mass; balanced stripping ratio; determination of yield, location of the production, calculation of infrastructure of the engineering quantity, transition period, etc.).

(6) Blasting design.

(7) Overlapping probability calculation.

1.3 The mining area and some requirements

(1) This design is mainly aimed at the Western ore section (No. I and No. II ore bodies) with more detailed geological work. According to the mining area scope provided by the owner, 460m is released from the central connection of three explosive depots in the explosive depot area, and the boundary line is used as the mining boundary to determine the mining area in the eastern part of the western mining section (ore bodies I and II); in the southern, northern and western areas, the mining area boundary is provided by the owner.

(2) According to the deposit occurrence conditions and the lowest erosion datum level of 219.96m in the west section of the cement limestone mining area, the lowest mining elevation of 220 m is designed.

(3) The safe distance of blasting is 200 m, and the western boundary of the mining area is 300 m from the local highway.

(4) Within the scope of the applied mining area, delineate the mining boundary.

(a) Strictly enforce the laws and regulations of the State and the relevant policies and policies of the State regarding the construction of projects.

(b) Where safety in production and environmental protection are involved, they shall be strictly implemented in accordance with the laws and regulations of the State and the requirements of relevant government documents.

(c) Implementing the policy of energy conservation and saving electricity and water. The purpose of this research is to complete a cement limestone mine of 700 million tons/ of mining design a year.

1.4 The geographical location and traffic conditions.

The cement limestone mining area is located in the northeast direction of Jiaozuo city, about 12 km away from Jiaozuo urban area. It is under the jurisdiction of Anyang urban and rural areas of Macun District and Xicun Township of Xiuwu County. The boundary between Xiuwu county and Jiaozuo urban area is bounded by the East-West main ridge of the area. Xicun Township of Xiwu County in the north of the mining area and Anyang urban and rural areas of Macun district of Jiaozuo city is in the South.

The cement limestone mining area starts from Sanmenhe in the west, and the Wangyao limestone mine in Zhengzhou Aluminum Factory in the east. The limestone mining area is 4.76km2, bounded by the Geliaofan fault (F1) in the north, and from the south to Houcun-Ximiaoqiancun North-Line. Geographical coordinates are 113°17′45″-113°19′52″, in east longitude, 35°19′17″-35°20′50” in northern latitude. There is a railway passes through 10km to the south of Jiaozuo, connecting Beijing-Guangzhou line in the east, Longhai line in the west, and Jiaozuo-Taiyuan railway directly links Shanxi Province. The north, south, West and central part of the mining area are connected by local highways and rural highways, and the traffic is very convenient.

1.5 Use of Lime Rock

Limestone is a rock with an enormous diversity of uses. It could be the one rock that is used in more ways than any other. Most limestone is made into crushed stone and used as a construction material. It is used as a crushed stone for road base and railroad ballast. It is used as an aggregate in concrete. It is fired in a kiln with crushed shale to make cement.

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: