XZS50型旋振筛设计毕业论文

2020-04-15 16:53:02

摘 要

旋振筛是一种将物料颗粒按照粒径分级的设备,广泛用于食品、冶金、农产品等多个行业。它主要的用途是按照物料所需要求,实现物料的筛分,因其运转平稳、工作可靠、效率高,且结构简单、经济性好等特点,在工业现场有着广泛的使用。

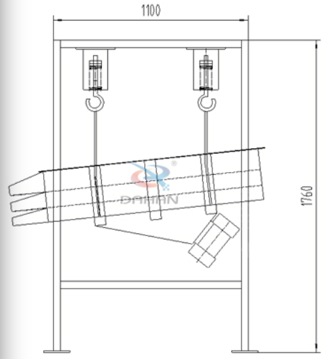

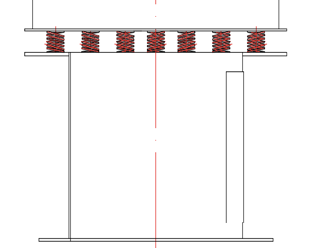

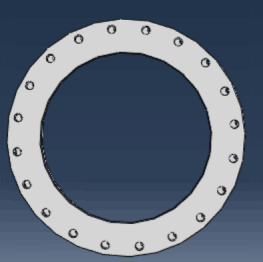

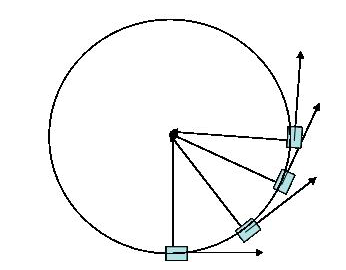

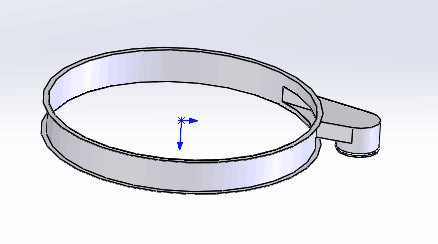

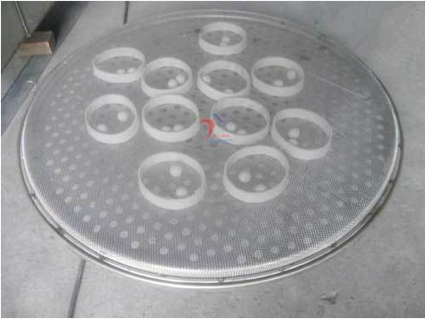

本次设计的XSZ500旋振筛,其主要用于长石釉料颗粒的筛分。文章第一章首先论述了振动筛在工业场合中的应用(瓜尔胶的筛分、煤炭的筛分等)、比较了国内外的发展状况(前期落后于国外发达国家,改革开放后,科学技术快速发展,伴随振动理论的深入研究,逐步缩短差距)、振动筛的分类(按筛分原理可分为干式筛分机和湿式筛分机,按激振源可分为自定心激振筛和激振筛),最后着重介绍了旋振筛的工作原理(将电机的转动通过轴上,激振筛体,转变为物料的振动)及其应用场合(占地面积小的工业现场)。文章第二章浅析旋振筛物料在筛面上的运动轨迹,筛面上物料的运动轨迹决定筛分的整体效果,包括平面、垂直面、空间的运动轨迹,旋振筛筛面上的物料的运动轨迹的不同是通过调节两偏心块的夹角实现的,不同的夹角实现不一样的物料轨迹。根据所需筛分的长石釉料的产量要求:0.4t/h-0.5t/h,结合釉料在制陶产业中的质量的要求,综合论证旋振筛是合理的选择。接着进行相应的任务分析,考虑设计中的难点,对不同的设计方案进行优化论证,对关键部分进行合理的设计,对主要工艺参数进行有效的选择,如:抛掷指数、筛面倾角、筛箱振幅、振动频率、振动强度等等,在旋振筛的整体设计中包括:筛筐、筛面支撑方案设计、筛筐与筛面连接的方案设计。再根据釉料颗粒所需的产量,确定旋振筛的处理量,设计合理的筛面,选择合适目数的筛网。筛箱(筛框与筛架)的是旋振筛的重要组成部分,它承载物料,参与整体振动,筛箱的设计有着极大的意义,通过一定的力学分析,确定旋振筛的尺寸。参振质量包括筛箱的质量、长石釉料颗粒的质量还有其他一部分的参与振动的质量,在确定参振质量的基础上,设计合适的弹簧,确定其圈数、中径尺寸、大径尺寸等。通过建立力学模型,确定旋振筛的主矢、主矩,以此选用合适功率的电机。根据电机所能传递的扭矩,选用适合要求的联轴器,胎轮式联轴器弹性好、扭转刚度小、具有较强的补偿两轴偏差的能力,满足此次设计的要求。根据计算出的轴的最小尺寸,结合联轴器轴孔的尺寸,设计阶梯轴,因电机竖直放置,且装有上下偏心块,受到较大的轴向力,为了减少轴所受的轴向力,合理的选择轴承:采用一对向心安装的角接触球轴承,相互抵消轴所受力。阶梯轴各段的尺寸、大小,根据轴上两偏心块转动时产生的偏心力进行相应的校核,包括:强度、刚度校核,绘制相应的弯矩图,满足整体生产的要求。

Abstract

Rotary vibrating screen is a kind of equipment that classifies material particles according to their particle size. It is widely used in food, metallurgy, agricultural products and other industries. Its main purpose is to screen materials according to the requirements of materials. Because of its smooth operation, reliable operation, high efficiency, simple structure and good economy, it has been widely used in industrial field.

The XSZ500 rotary vibration screen designed in this paper is mainly used for screening feldspar glaze particles. In the first chapter, the application of vibrating screen in industrial occasions (guar gum screening, coal screening, etc.) is discussed, and the development situation at home and abroad is compared (lagging behind developed countries in the early stage, rapid development of science and technology after reform and opening up, accompanied by in-depth study of vibration theory, gradually shortening the gap), and the classification of vibrating screen (according to screening principle, it can be divided into dry screening). Machine and wet screening machine can be divided into self-centering exciting screen and exciting screen according to exciting source. Finally, the working principle of rotating screen (transforming motor rotation through shaft, exciting screen body into material vibration) and its application occasion (occupying small area of industrial site) are emphatically introduced. In the second chapter, the trajectory of the material on the screen surface is analyzed. The trajectory of the material on the screen surface determines the overall effect of screening, including the trajectory of plane, vertical plane and space. The trajectory of the material on the screen surface is different by adjusting the angle between the two eccentric blocks, and different angle realizes different material trajectory. According to the output requirement of feldspar glaze screened: 0.4t/h-0.5t/h, combined with the quality requirement of glaze in ceramics industry, it is proved that the rotary screen is a reasonable choice. Then the corresponding task analysis is carried out, considering the difficulties in the design, optimizing and demonstrating the different design schemes, reasonably designing the key parts, and effectively selecting the main process parameters, such as throwing index, screen inclination angle, screen box amplitude, vibration frequency, vibration intensity, etc. In the overall design of rotary vibrating screen, the scheme of screen basket and screen support is included. The scheme design of connection between design and screen basket and screen surface. Then according to the output of glaze granules, the processing capacity of rotary vibrating screen is determined, the reasonable screen surface is designed, and the appropriate mesh number is selected. Screen box (screen frame and screen frame) is an important part of rotary vibration screen. It carries materials and participates in the overall vibration. The design of screen box has great significance. Through certain mechanical analysis, the size of rotary vibration screen is determined. The vibration quality includes the quality of screen box, feldspar glaze particles and other parts of the vibration quality. On the basis of determining the vibration quality, a suitable spring is designed to determine the number of circles, the size of medium diameter and the size of large diameter. By establishing mechanical model, the principal vector and principal moment of the rotary screen are determined, and the suitable power motor is selected. According to the torque that the motor can transmit, the suitable coupling is selected. The tyre coupling has good elasticity, small torsional stiffness and strong ability to compensate the deviation of two axes, which meets the requirements of this design. According to the calculated minimum size of the shaft, combined with the size of the shaft hole of the coupling, the stepped shaft is designed. Because the motor is placed vertically and equipped with upper and lower eccentric blocks, it is subjected to greater axial force. In order to reduce the axial force on the shaft, a reasonable choice of bearings is to adopt a pair of centripetal angular contact ball bearings to offset the force on the shaft. The dimensions and sizes of each section of the stepped shaft are checked according to the eccentric force produced by the rotation of the two eccentric blocks on the shaft, including strength and stiffness checks, and the corresponding bending moment diagrams are drawn to meet the requirements of the overall production.

Key words: Rotary vibrating screen、feldspar、path of particle

目录

摘要 I

Abstract III

第一章 绪论 1

1.1振动筛的应用 1

1.2振动筛的发展 1

1.3振动筛的分类 2

1.4旋振筛 3

第二章 旋振筛的物料轨迹分析 4

2.1筛面上任意一点在水平面内位移 4

2.2筛面上任意一点垂直方向的位移 5

2.3筛面上任意一点的空间运动轨迹 5

2.4筛面物料运动规律的调整 5

第三章 总体方案的确定 7

3.1 设计任务分析 7

3.1.1设计要求 7

3.1.2任务分析 7

3.2整体方案的设计 8

3.2.1振动筛的形式 8

3.2.2筛筐、筛面支撑方案设计 8

3.2.3筛筐与筛面连接的方案设计 9

3.3振动筛工艺参数的选择 9

3.3.1抛掷指数 9

3.3.2筛面倾角 10

3.3.3筛箱振幅 10

3.3.4振动频率 10

3.3.5振动强度 11

第四章 旋振筛主要零部件的设计 12

4.1筛面的选择与设计 12

4.2筛筐与筛架的设计 13

4.3弹簧设计计算 14

4.3.1参振质量计算 14

4.3.2 弹簧尺寸计算 14

4.4电机的选择 17

4.4.1建立力学模型 17

4.4.2电机功率计算与选择 18

4.5轴的设计与计算 19

4.5.1阶梯轴的设计 19

4.5.2轴的强度校核 21

结语 23

参考文献 24

致谢 26

第一章 绪论

1.1振动筛的应用

筛分设备是将粒径大小不同的混合物料,经过不同孔径的筛网筛分成不同粒径等级的机械设备。在煤炭、材料、冶金、建材、电力、化工、食品等许多工业部门振动筛有着极大的应用。

在煤炭工业的生产中常用的筛分设备主要有:固定筛、滚轴筛、振动筛,随着产业规模的发展,振动筛已经成为一种常见的筛分机械,并逐渐取代固定筛、滚动筛,煤炭的分级、拖泥、脱水、拖介等主要依靠振动筛,其操作简单、工作可靠、效率也高,同样在我国的其他领域有着出色的发挥。

瓜尔胶的生产中,振动筛起着举足轻重的作用,筛分环节决定了产品的质量,粒径合格的物料透筛后进入灌装机,粒径不合格的瓜尔胶将进一步粉碎,直至达到粒径要求。

改革开放以来,随着科学技术的进步以及振动原理的深入研究,出现了许多新型的筛分设备,在生产应用中,极大促进了工业生产的发展,提升了众多行业的经济效益。

1.2振动筛的发展

16世纪初期,工业革命的开始,新兴的工业国家(英国、德国)随着对煤炭需求量的增大,对碳粉精度的增加,开始了对筛分机械的研制[1]。工业革命进入中期,也就是18世纪,早期研制筛分机械的工业国家对于筛分机的研究也随着工业革命的进程飞速发展。到21世纪的今天,科学技术高速发展,振动筛的理论变得日趋成熟,振动筛的机械加工工艺也变得如火纯清[1]。以德、美、日为代表的老牌工业强国,他们在筛分设备上的研究在国际上处于领先位置,如德国申克公司旗下不同型号的筛分设备就有200多种,STK公司掌握着大量的关于振动筛的筛分技术,其技术全,性能好在筛分机械界着实出名;再如美国RNO公司研制的DF型双频旋振筛,其采用不同频率的电机填补了领域内的空白;日本在振动筛领域的研究也较为出色,东海株式会社与RXR公司共同研制的垂直料流第一次将旋转运动和旋回运动结合起来,大胆的创新值得我们借鉴[1]。

由于我国工业发展缓慢,工业基础薄弱,对于振动理论的研究较先进国家落后,20世纪50年代,我国的筛分机械才开始有了发展,到如今的相对成熟,我国振动机械的发展走过了仿制、自行研制、引进提高的三阶段。

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: