磁流体动压润滑与密封特性的试验研究毕业论文

2020-04-15 17:40:05

摘 要

流体动压润滑在机械密封设备当中已经得到广泛的应用。普遍应用的流体动压润滑机械密封在工作状态下是不可控制的,在工况(如操作压力)发生改变时,不能够迅速的做出回应,从而导致泄露。当设备在不断更新换代、自动化和集成化的同时,机械密封慢慢的向能够适应工况,可以进行自我调节的方向发展。磁流体作为新型的磁性材料,能够在磁场的作用下展现出不同的物理性能,其中粘度的可控性使其在流体的润滑和密封的领域中获得了应用。让磁流体作为密封介质,使其介入非接触式机械密封当中,形成新的磁流体机械密封,研究磁场强度对磁流体润滑机械密封的影响程度。本文的主要工作和得出的结论包括:

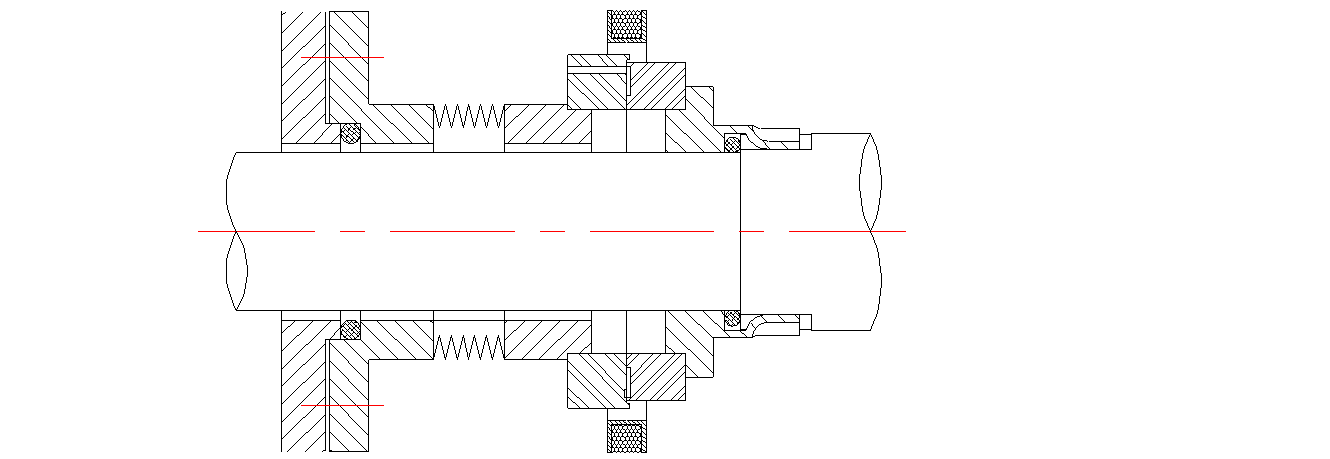

- 相对于传统的非接触式机械密封,选用一种新的磁流体润滑的非接触是机械密封结构。该密封结构是将磁流体作为密封润滑介质流入动静环之间的端面内,并且在密封环的外部设置一个磁场发生器。同时,在密封结构内设置多个传感器并保证能够实时检测到密封性能参数。磁场强度随着磁场发生器的电流的变化而发生相应的变化,从而做到磁流体膜的粘度发生变化,达到机械密封性能参数得到调节的目的。

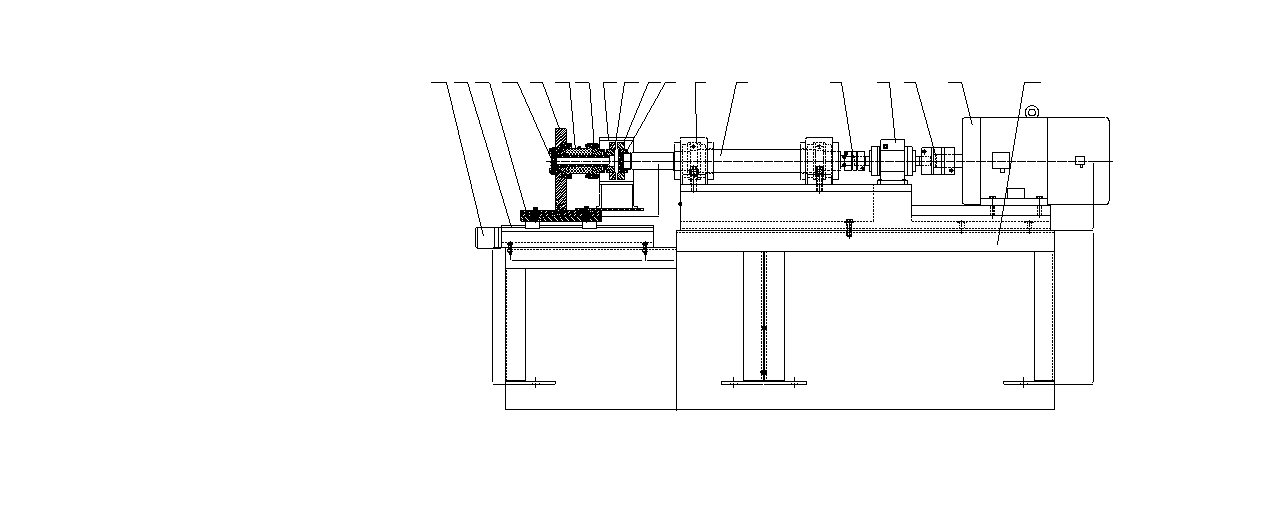

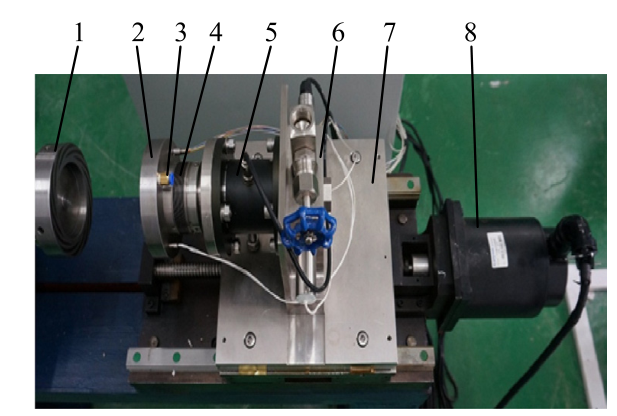

- 为了能得到密封结构的性能改变,本文参与设计并使用了一台机械密封试验装置,具有高自动化、操作便捷和通用性强。在静环内侧装有一个可以得到动压润滑膜膜厚压力的电涡流位移传感器和静环端面装置一个可测得密封环温度和动压润滑膜压压力的温度压力传感器;弹性元件上装置一个可以测的摩擦扭矩和端面比压的压-扭一体传感器;为测密封腔温度和压力,在密封腔内装有温度和压力传感器。根据所设传感器可知,本装置可以控制机械密封端面比压、润滑介质供给压力、转轴转速、密封介质压力和磁场强度。

- 运用解析法观察了操作参数对磁流体润滑机械密封的密封性能的影响、规律。在试验装置上研究了转轴转速和磁场强度对密封性能的影响程度。研究发现,摩擦扭矩会随着磁场强度的变大而不断增大;在转速增大的同时会引起摩擦扭矩的不断变小。

- 根据试验得出的试验数据,在磁流体润滑机械密封的密封介质压力和转轴转速改变时会引起液膜密封压力和密封介质压力不平衡二发生泄漏现象。此时,通过转速和压力的传感器感应并检测到工作状态,再通过改变磁场发生器的电流强度使工作状态重归平衡,实现对密封性能的控制。

关键词 磁流体 流体动压效应 机械密封 润滑

Experimental Study on Hydrodynamic Lubrication and Sealing Characteristics of Magnetic Fluid

ABSTRACT

Hydrodynamic lubrication has been widely used in mechanical sealing equipment. The commonly used hydrodynamic lubrication mechanical seal is uncontrollable in the working state, and cannot respond quickly when the working condition (such as operating pressure) changes, thus leading to leakage. When the equipment is constantly updated, automated and integrated, the mechanical seal slowly to be able to adapt to the working conditions, the direction of self-regulation. As a new type of magnetic material, magneto fluid can show different physical properties under the action of magnetic field, among which the controllable viscosity makes it applied in the field of fluid lubrication and sealing. The magnetic fluid is used as the sealing medium to intervene in the non-contact mechanical seal to form a new magnetic fluid mechanical seal. The influence of magnetic field strength on the mechanical seal of magnetic fluid lubrication is studied. The main work and conclusions of this paper include:

(1) Compared with the traditional non-contact mechanical seal, a new non-contact magnetic fluid lubrication mechanical seal structure is selected. The sealing structure is that magnetic fluid is used as sealing lubrication medium to flow into the end face between stationary and stationary rings, and a magnetic field generator is set outside the sealing ring. At the same time, multiple sensors are installed in the sealing structure to ensure real-time detection of sealing performance parameters. The magnetic field intensity changes with the current of the magnetic field generator, so that the viscosity of the magnetic fluid film changes and the mechanical sealing performance parameters can be adjusted.

(2) In order to get the performance change of sealing structure, this paper participated in the design and use of a mechanical sealing test device, which has high automation, convenient operation and strong universality. An eddy current displacement sensor which can obtain the thickness of the film of the dynamic pressure lubrication film and a temperature and pressure sensor which can measure the temperature of the sealing ring and the pressure of the dynamic pressure lubrication film are installed inside the static ring. A pressure-torsion sensor with measurable frictional torque and end specific pressure is mounted on the elastic element; In order to measure the temperature and pressure of the sealing chamber, a temperature and pressure sensor is installed in the sealing chamber. According to the sensor, the device can control the pressure ratio of mechanical seal end face, lubricating medium supply pressure, rotating shaft speed, sealing medium pressure and magnetic field strength.

(3) The influence and rule of operating parameters on the sealing performance of magnetic fluid lubrication mechanical seals are observed by analytic method. The effects of rotating speed and magnetic field strength on sealing performance were studied on the test equipment. It is found that friction torque increases with the increase of magnetic field strength. When the speed increases, the frictional torque decreases.

(4) According to the test data obtained from the test, when the pressure of sealing medium and rotation speed of magnetic fluid lubrication mechanical seal change, it will cause the imbalance of liquid film sealing pressure and sealing medium pressure and leakage phenomenon. At this time, the working state is sensed and detected by the sensor of speed and pressure, and then the working state is rebalanced by changing the current intensity of the magnetic field generator, so as to control the sealing performance.

KEYWORDS: Magnetic fluid;Hydrodynamic action;Mechanical seal;Lubricatio

目 录

摘 要 I

ABSTRACT III

引 言 1

第一章 磁流体性质及应用与流体动压密封基本原理 3

1.1 磁流体的概念及性质 3

1.2 磁流体的应用 4

1.3 流体动压密封基本原理 5

第二章 磁流体润滑密封试验装置 9

2.1 试验装置基本原理 9

2.2 试验装置的基本机构 9

2.3 试验装置的设计 11

2.4 设备评估 14

2.4.1 经济性评估 14

2.4.2 安全评估 15

第三章 磁流体润滑密封的试验 16

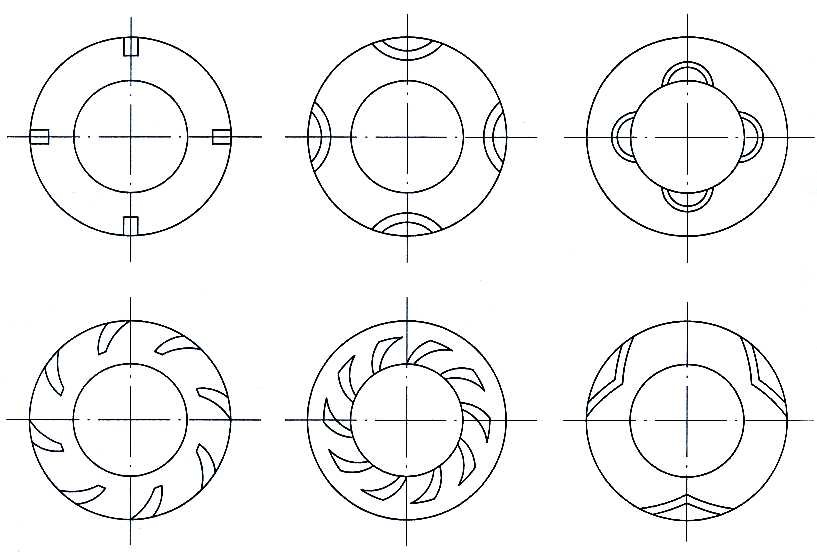

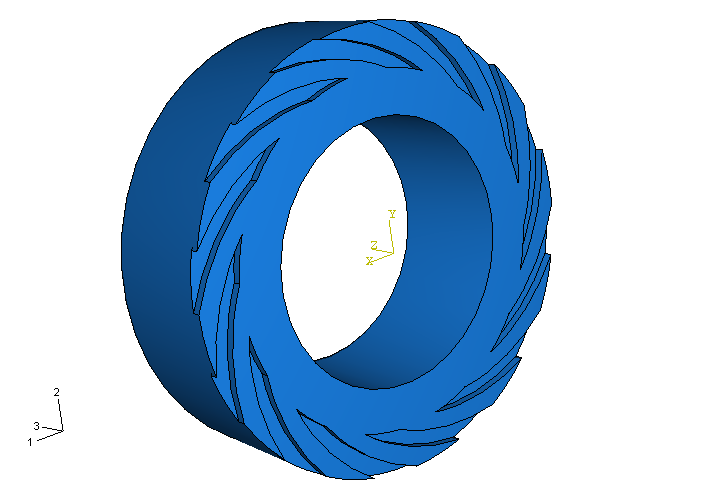

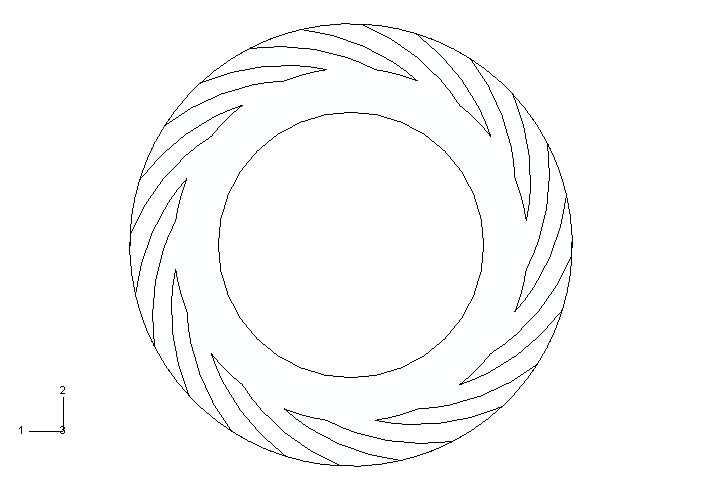

3.1 密封的基本结构 16

3.2 磁流体润滑机械密封工作原理及试验流程 16

3.3 磁流体动压润滑及密封的主要参数 18

3.4 密封试验研究 19

3.4.1 试验条件 19

3.4.2 试验内容 19

3.4.3 试验结果的分析与研究 22

第四章 结论与展望 24

4.1 总结 24

4.2 对以后的展望 25

参考文献 26

引言

机械密封是流体密封中最常见的型式,是旋转设备防止泄露的重要部件,其中非接触式机械密封利用润滑膜的动压效应使密封环端面保持非接触,边减小摩擦边实现介质的密封[1]。近几年来,通过动压效应,磁流体逐渐被应用到机械设备的密封和润滑之中。磁流体密封作为一项新技术具有较小的摩擦功耗、密封严密零泄露、寿命长、可靠性高、污染率低、高速旋转下使用等优点[2]。

当动、静环间的端面压力比不发生变化时,润滑膜的动压并不能适应被密封介质压力的波动。根据磁场强度对磁流体的粘度有一定的控制特性,磁流体会被当成润滑介质被引入非接触式机械密封动静环的端面之间,通过操控外加的磁场强度来对磁流体的粘度进行调节,从而在磁流体膜处产生不同的动压。实现磁流体的密封作用[3-5]。

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: