316L不锈钢超饱和气体渗碳层残余应力数值计算毕业论文

2020-05-28 06:59:15

摘 要

本课题采用低温超饱和气体渗碳(LTCSGC)对316L不锈钢进行表面强化处理,研究在470℃条件下,经20%CO/30%H2/50%N2处理5h、15h和30h后渗碳层的微观特性和残余应力分布规律。主要工作和结论如下:

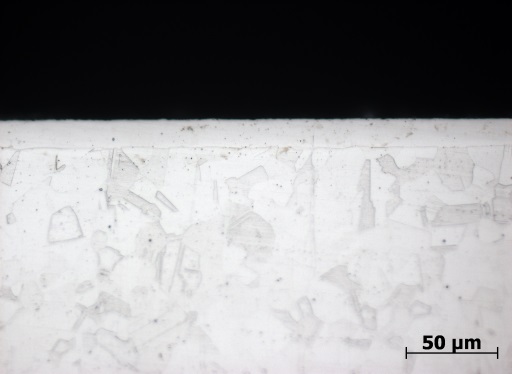

(1)建立了一套奥氏体不锈钢LTCSGC表面强化处理试验系统,利用该试验系统进行了316L奥氏体不锈钢LTCSGC试验,并对渗碳层碳含量分布、表面相结构及表面残余应力进行测试。结果表明,经LTCSGC处理后,不锈钢表面碳含量显著提高,同时产生了压缩残余应力,其相结构主要为扩张奥氏体相(S相)。不锈钢表面碳含量和压缩残余应力均随着渗碳时间的增加而增加。当渗碳时间为30h时,渗碳层厚度约为35μm,不锈钢表面碳含量增加到2.56wt.%,压缩残余应力达到2175MPa。

(2)采用纳米压痕测试了渗碳试样的纳米硬度分布。结果表明,经5h渗碳处理后,试样表面纳米硬度从3.91GPa增加到6.08GPa,随着渗碳时间延长至30h,试样表面纳米硬度进一步提高到12.77GPa,为原始316L奥氏体不锈钢的3.27倍。

(3)基于Suresh模型,结合纳米压痕的试验测试与有限元模拟结果,研究了不同渗碳时间下渗碳层中残余应力的大小和分布,并将计算结果与XRD测试结果进行对比。结果表明,纳米压痕方法可以较好地应用于渗碳层残余应力的测量分析,其计算结果与根据穿透深度修正后的XRD测试结果吻合较好;渗碳层中残余应力与C含量为正比例线性关系。

关键词:低温超饱和气体渗碳 压缩残余应力 碳含量 扩张奥氏体相 有限元模拟

Numerical Calculation of Residual Stress for 316L Stainless Steel Treated by Low Temperature Colossal Supersaturation Gas Carburization

ABSTRACT

In this research, low temperature colossal supersaturation gas carburization (LTCSGC) was carried out on 316L stainless steel surface. The micro-characteristic and residual stress distributions of carburized layer treated in a mixture of 20%CO, 30%H2 and 50%N2 at 470℃ for 5h, 15h and 30h were investigated. The main conclusions are as follows:

(1) An experimental system for LTCSGC of austenitic stainless steel was designed and constructed. Low temperature colossal supersaturation gas carburization experiments for 316L stainless steel were carried out in the system, and carbon concentration distributions, surface phase constitution and residual stress of carburized layer were analyzed. The results reveal that the surface carbon concentration significantly increases after LTCSGC, which leads to surface compressive residual stress. The phase constitution of carburized layer surface is mainly composed of expanded austenite (S phase). The surface carbon concentration and compressive residual stress of stainless steel increases with carburization time. After LTCSGC for 30h, the depth of carburized layer reaches 35μm, the surface carbon concentration and compressive residual stress of stainless steel increases to 2.56wt.% and 2175MPa respectively.

(2) The nanohardness distributions of carburized samples were investigated by the nanoindentation. The results show that the surface nanohardness of stainless steel increases from 3.91GPa to 6.08GPa after LTCSGC for 5h. With the carburizing time increasing to 30h, the nanohardness reaches 12.77GPa, which is 3.27 times than the specimen without carburization.

(3) The residual stress distributions of carburized layer for different carburizing time were investigated by combined the experimental and ABAQUS finite element simulation results of nanoindentation based on Suresh model. The calculated results were compared with XRD test results. The results show that it is feasible to evaluate the residual stress in carburized layer using nanoindentation method, the calculated results agree with XRD test results modified according to the penetration depth. The residual stress is proportional to carbon centration.

Key Words:Low temperature colossal supersaturation gas carburization; Compressive residual stress; Carbon concentration; Expanded austenite phase; Finite element simulation

目 录

摘要…………………………………………………………………………………I

ABSTRACT………………………………………………………………………II

第一章 绪论………………………………………………………………………1

1.1 研究背景……………………………………………………………………1

1.2 金属材料的表面强化技术…………………………………………………1

1.2.1 表面强化技术的作用…………………………………………………1

1.2.2 表面强化技术的分类…………………………………………………2

1.3 化学热处理…………………………………………………………………4

1.3.1 化学热处理的分类……………………………………………………4

1.3.2 化学热处理的特点……………………………………………………4

1.4 传统渗碳表面强化技术……………………………………………………4

1.4.1 渗碳表面强化技术的分类……………………………………………5

1.4.2 渗碳的基本原理………………………………………………………5

1.4.3 渗碳表面强化技术的发展……………………………………………5

1.5 奥氏体不锈钢低温气体渗碳技术的研究现状……………………………7

1.5.1 低温气体渗碳技术的原理……………………………………………7

1.5.2 奥氏体不锈钢低温气体渗碳技术的研究进展………………………7

1.6 奥氏体不锈钢渗碳层残余应力的研究……………………………………8

1.7 本课题主要研究内容………………………………………………………9

参考文献…………………………………………………………………………9

第二章 低温超饱和气体渗碳试验研究…………………………………12

2.1 低温超饱和气体渗碳的基本过程…………………………………………12

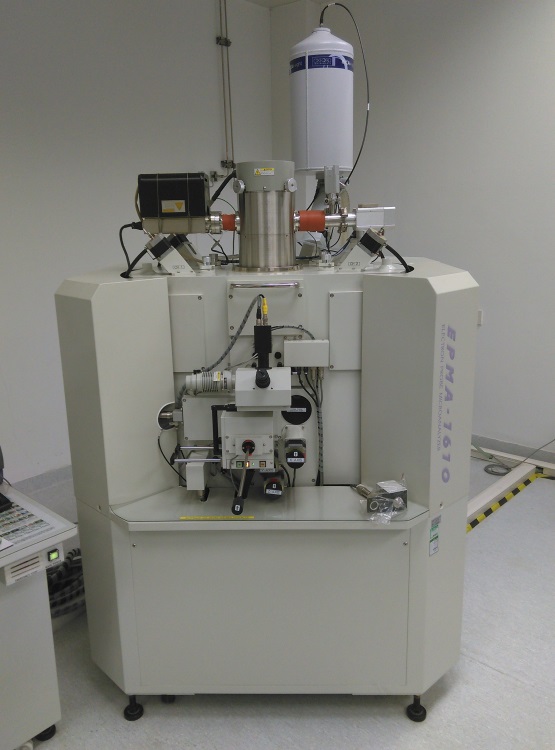

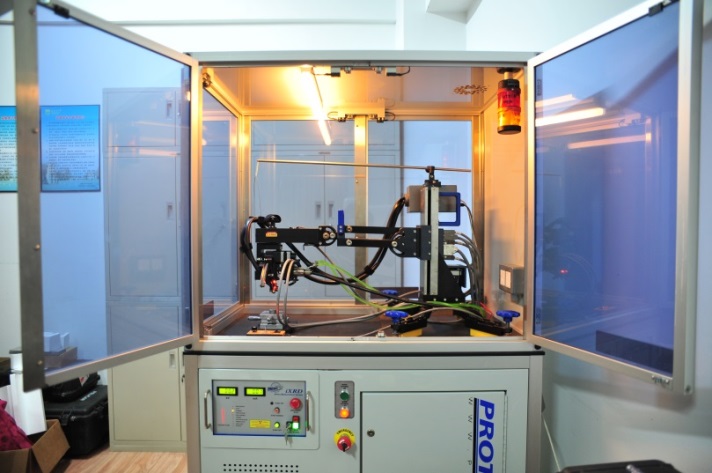

2.2 低温超饱和气体渗碳试验系统的设计与搭建……………………………13

2.2.1 供气系统……………………………………………………………13

2.2.2 流量控制系统………………………………………………………13

2.2.3 压力控制系统………………………………………………………15

2.2.4 气体混合系统………………………………………………………15

2.2.5 加热系统……………………………………………………………16

2.2.6 其他附件……………………………………………………………16

2.3 试验内容与方法……………………………………………………………17

2.3.1 试验材料与试样……………………………………………………17

相关图片展示: