掺氮碳材料的制备及其催化性能的研究毕业论文

2020-07-05 17:22:10

摘 要

介孔碳材料是一种新型的以碳为骨架的无机材料,与其他介孔材料一样,介孔碳材料有着规则的孔道结构、较大的孔隙率,而且因制备及处理的方法不同,其孔径可调,因此在催化、吸附和分离、超级电容器等领域有着巨大的应用前景。但传统的介孔碳材料亲水性较差,缺乏足够的活性吸附位点,在一定程度上限制了其应用。通过对其进行功能化修饰,掺杂N原子,能改变其表面特性和物理化学性质,拓宽其应用领域。醋酸丁酯是一种优良的有机溶剂,对许多的天然树脂有良好的溶解能力,常用于石油加工中作萃取剂以及塑料加工中作溶剂,也用于食用香料中。本文即以合成醋酸丁酯为基础,探究掺氮碳材料的制备及其催化性能。

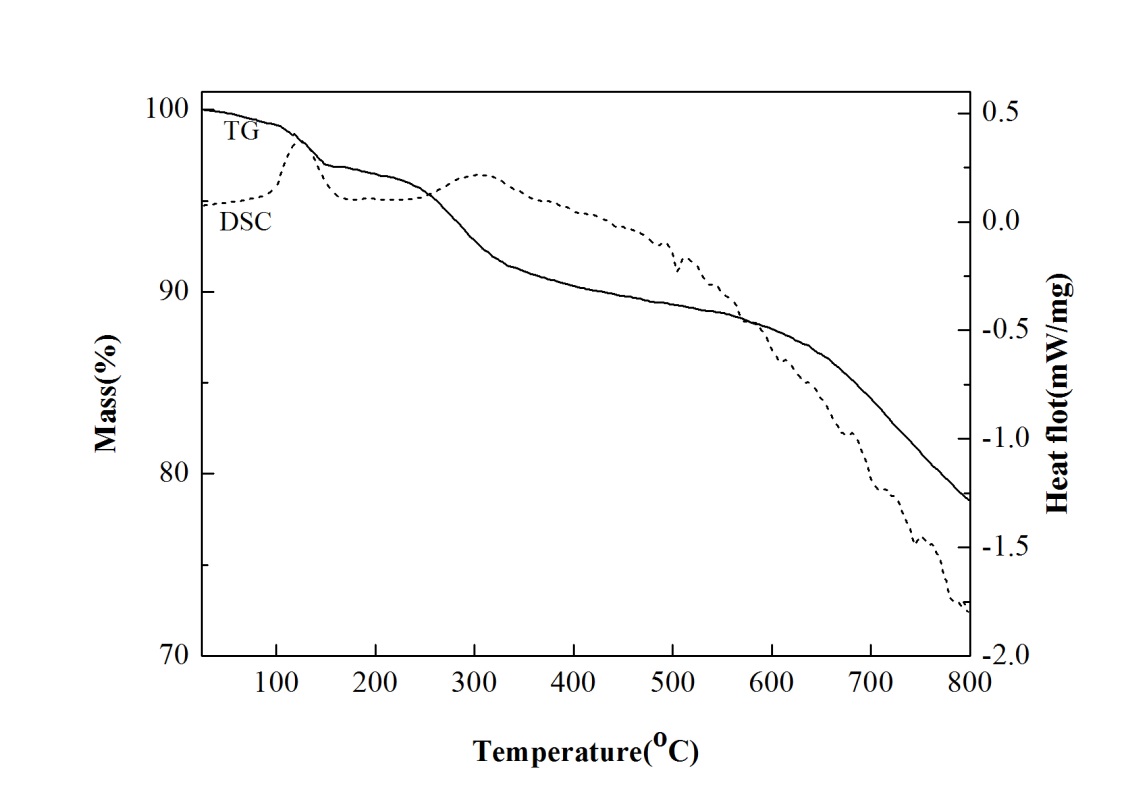

本文通过TEOS与淀粉、木质素水解,然后在550℃的温度下用氨气处理3h制得掺氮碳材料,最后用浓硫酸磺化得到氮掺杂碳硅固体酸催化剂。通过BET分析得知,催化剂制备时,淀粉与木质素的质量比为3:2,其比表面积和孔体积相对最大。通过热重分析可知该催化剂热稳定性较好。

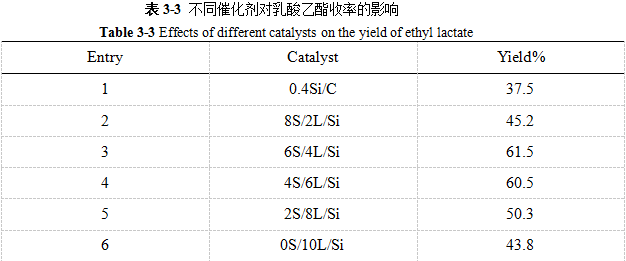

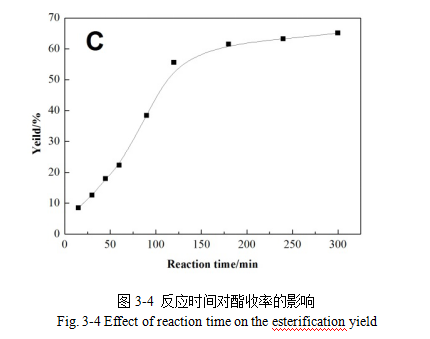

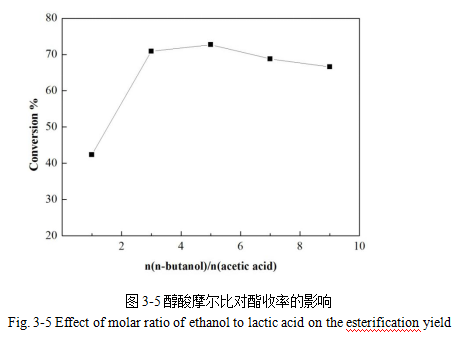

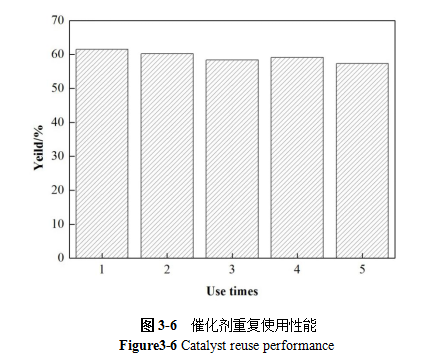

在乙酸和正丁醇的酯化反应中,通过改变淀粉与木质素的比例发现,在淀粉与木质素的质量比为6:4的配比下,催化效果最好。在此配比的催化剂进行大量对比实验,确定了在100℃的温度下,正丁醇与乙酸的摩尔比为5:1,反应3h为最佳工艺条件。催化剂重复使用五次后,发现醋酸丁酯的收率仅下降5%,表明该催化剂具有良好的重复使用性能。

关键词:掺氮碳材料 催化剂 酯化反应

Preparation of Nitrogen-doped Carbon Materials and Their Catalytic Performance

Abstract

The mesoporous carbon material is a novel inorganic material with a carbon skeleton. Like other mesoporous materials, the mesoporous carbon material has a regular pore structure and a large porosity, and its preparation and processing methods are different. The aperture is adjustable, so it has a huge application prospect in the fields of catalysis, adsorption and separation, super capacitor and so on. However, traditional mesoporous carbon materials have poor hydrophilicity and lack sufficient active adsorption sites, which limits their application to a certain extent. Through its functional modification, doping of N atoms, it can change its surface properties and physical and chemical properties, and broaden its application fields. Butyl acetate is an excellent organic solvent and has good solvency for many natural resins. It is often used as an extractant in petroleum processing and as a solvent in plastics processing and also in food flavorings. This article is based on the synthesis of butyl acetate, to explore the preparation of nitrogen-doped carbon materials and its catalytic performance.

In this paper, nitrogen-doped carbon materials were prepared by hydrolyzing TEOS with starch and lignin, and then treated with ammonia gas at a temperature of 550° C. for 3 h, and finally sulfonated with concentrated sulfuric acid to obtain a nitrogen-doped carbon-silicon solid acid catalyst. By BET analysis, the mass ratio of starch to lignin during the preparation of the catalyst was 3:2, and its specific surface area and pore volume were relatively largest. Through thermogravimetric analysis, the thermal stability of the catalyst is better.

In the esterification of acetic acid and n-butanol, the ratio of starch to lignin was changed. It was found that the ratio of starch to lignin in the mass ratio of 6:4 had the

best catalytic effect. A large number of comparative experiments were carried out on this matching catalyst, and it was determined that the molar ratio of n-butanol to acetic acid was 5:1 at a temperature of 100[deg.] C. The optimum reaction conditions were 3 h. After repeated use of the catalyst five times, it was found that the yield of butyl acetate only decreased by 5%, indicating that the catalyst has good reusability.

Keywords: Nitrogen-doped carbon material Catalyst Esterification

目录

摘要 I

Abstract II

第一章 文献综述 1

1.1 氮掺杂碳材料简介 1

1.2 氮掺杂碳材料的制备 1

1.2.1 模板法 1

1.2.2 化学气相沉积法 2

1.2.3 后处理法 2

1.2.4 水热法 4

1.3 氮掺杂介孔碳材料的应用 4

1.3.1 氮掺杂介孔碳材料在生物医药领域的应用 4

1.3.2 氮掺杂介孔碳材料在储电领域的应用 4

1.3.3 氮掺杂介孔碳材料在吸附分离中的应用 5

1.3.4 氮掺杂多孔碳材料在催化反应中的应用 5

第二章 实验部分 6

2.1 实验药品及仪器 6

2.2 催化剂的制备 6

2.2.1 掺N碳材料催化剂载体的制备 6

2.2.2 掺N碳材料催化剂的制备 7

2.3 酯化反应 7

2.4 产物分析 7

第三章 结果与讨论 9

3.1 催化剂的表征 9

3.1.1 BET分析 9

3.1.2 热重分析 10

3.2 催化剂酸量的测定 10

3.3 催化剂性能分析 11

3.3.1 前驱体不同配比的影响 11

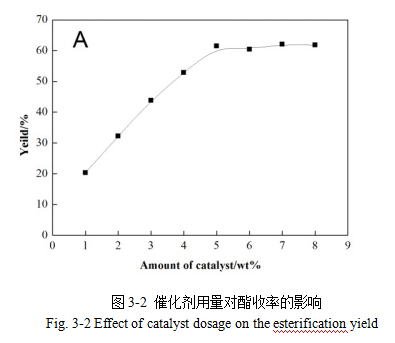

3.3.2 催化剂用量影响 12

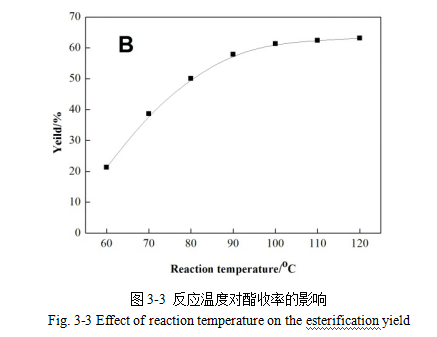

3.3.3 反应温度影响 12

3.3.4 反应时间影响 13

3.3.5 醇酸摩尔比的影响 14

3.3.6 催化剂重复使用性能 15

第四章 总结与展望 16

参考文献 17

致谢 17

第一章 文献综述

- 氮掺杂碳材料简介

介孔碳材料指具有规则而均匀孔道结构的碳材料,其具有较高的比表面积、较大的孔隙率,因而在吸附分离、电容器等领域应用较多。

氮原子与碳原子结构相似,相比碳原子,氮原子多一个核外电子,因而在掺氮碳材料中的碳原子正电荷密度较高,同时N原子孤对电子和碳原子晶格大π键之间存在共轭作用[2],由于这些特点,掺氮碳材料具有优良的电化学性能和催化性能[3]。碳材料掺杂N后极大的提升了催化剂的活性和催化剂的耐用性,改善了吸附和催化性能[4]。

- 氮掺杂碳材料的制备

- 模板法

- 氮掺杂碳材料的制备

(A)硬模板法

相关图片展示: