高强泡沫混凝土的微观结构外文翻译资料

2022-01-04 22:13:53

英语原文共 8 页,剩余内容已隐藏,支付完成后下载完整资料

高强泡沫混凝土的微观结构

摘要

- Foam concretes are divided into two groups: on the one hand the physically foamed

- concrete is mixed in fast rotating pug mill mixers by using foaming agents.

- This concrete cures under atmospheric conditions.

- On the other hand the autoclaved aerated concrete is chemically foamed by adding aluminium powder.

- Afterwards it is cured in a saturated steam atmosphere.

1.泡沫混凝土分为两组:一方面是物理发泡的

2.通过使用发泡剂将混凝土在快速旋转的搅拌机混合器中混合。

3.这种混凝土在大气条件下固化。

4.另一方面,蒸压加气混凝土通过添加铝粉进行化学发泡。

5.然后在饱和蒸汽气氛中固化。

- New alternatives for the application of foam concretes arise from the combination of chemical foaming and air curing in manufacturing processes.

- These foam concretes are new and innovative building materials with interesting properties: low mass density and high strength.

- Responsible for these properties are the macro-, meso- and microporosity.

- Macropores are created by adding aluminium powder in different volumes and with

different particle size distributions.

- However, the microstructure of the cement matrix is affected by meso- and micropores.

- In addition, the matrix of the hardened cement paste can be optimized by the specific use of chemical additives for concrete.

1.泡沫混凝土应用的新替代品来自于制造过程中的化学发泡和空气固化。

2.这些泡沫混凝土是新型和创新的建筑材料,具有有趣的特性:低质量密度和高强度。

3.负责这些属性的是宏观,中观和微观。

4.大孔是通过添加不同体积的铝粉而制成的不同的粒度分布。

5.然而,水泥基质的微观结构受中孔和微孔的影响。

6.此外,硬化水泥浆的基质可以通过特定用于混凝土的化学添加剂来优化。

- The influence of aluminium powder and chemical additives on the properties of the

microstructure of the hardened cement matrices were investigated by using petrographic

microscopy as well as scanning electron microscopy.

铝粉和化学添加剂对铝合金性能的影响通过岩相学研究了硬化水泥基体的微观结构显微镜以及扫描电子显微镜。

- 介绍

- Mineral-bound foams with porous structure and low mass density have established themselves in the construction industry.

- These fine-grained concretes are based on German standard DIN 4164, which in the meantime is no longer valid.

- They have a mass density le;2000 kg/m3 and are classified as lightweight concretes [14]. Subject to the production processes, mineral-bound foams are called autoclaved aerated concrete or foam concrete.

- The characteristics of these building materials are described in [4,7–12,14].

1.具有多孔结构和低质量密度的矿物结合泡沫已在建筑业中建立起来。

2.这些细粒混凝土基于德国标准DIN 4164,同时不再有效。

3.它们的质量密度le;2000kg/ m3,被归类为轻质混凝土[14]。 根据生产过程,矿物结合的泡沫被称为高压灭菌的充气混凝土或泡沫混凝土。

4.这些建筑材料的特性在[4,7-12,14]中有描述。

- In this paper, a methodology is presented for controlling the characteristics of air hardening, mineral-bound foams,which contribute to the expansion of the application type of these building materials.

- Already well-known manufacturing processes can be developed further in such a manner that the new resulting lightweight concretes receive reproducible characteristics.

- In this way, the requirements of the modern building task can be fulfilled, also within the field of design.

- For the description and evaluation of the microstructure of mineral-bound foams, light microscopy combined with digital image analysis [16], as well as scanning electron microscopy are suitable tools.

1.在本文中,提出了一种控制空气硬化,矿物结合泡沫特性的方法,这有助于扩大这些建筑材料的应用类型。

2.已经众所周知的制造工艺可以进一步发展,使得新生产的轻质混凝土具有可再现的特性。

3.通过这种方式,可以在设计领域内满足现代建筑任务的要求。

4.对于矿物结合泡沫的微观结构的描述和评估,光学显微镜结合数字图像分析[16],以及扫描电子显微镜是合适的工具。

2.技术基础

- Foam is a dispersive system made of gas and liquid and/or gas and solids, where the proportion of gaseous volume is dominant.

- With all genuine foams, each individual bubble represents a cavity closed in itself, with no gas-filled connections between neighbouring gas bubbles.

- In the foam, the gas is an intermittent or dispersive phase, while the continuous phase exists as a matrix or liquid [8].

1.泡沫是由气体和液体和/或气体和固体制成的分散系统,其中气体体积的比例占主导地位。

2.对于所有真正的泡沫,每个单独的泡沫代表自身封闭的空腔,在相邻的气泡之间没有充气连接。

3.在泡沫中,气体是间歇或分散相,而连续相以基质或液体形式存在[8]。

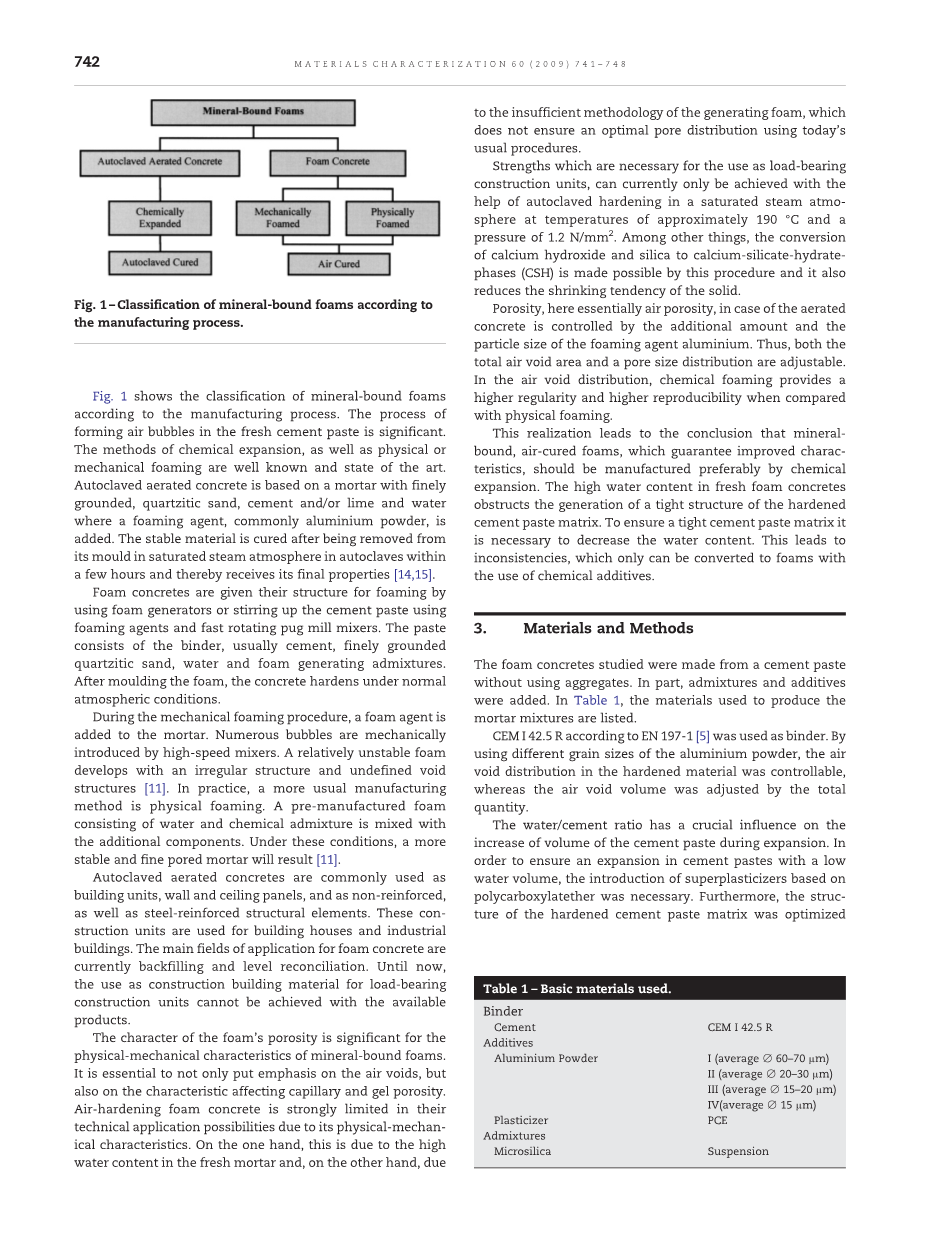

- Fig. 1 shows the classification of mineral-bound foams according to the manufacturing process.

- The process of forming air bubbles in the fresh cement paste is significant.

- The methods of chemical expansion, as well as physical or mechanical foaming are well known and state of the art.

- Autoclaved aerated concrete is based on a mortar with finely grounded, quartzitic sand, cement and/or lime and water where a foaming agent, commonly aluminium powder, is added.

- The stable material is cured after being removed from its mould in saturated steam atmosphere in autoclaves within a few hours and thereby receives its final properties [14,15].

1.图1显示了根据制造过程的矿物结合泡沫的分类。

2.在新鲜水泥浆中形成气泡的过程是重要的。

3.化学膨胀方法以及物理或机械发泡是众所周知的和现有技术。

4.蒸压加气混凝土基于具有精细研磨的石英砂,水泥和/或石灰和水的砂浆,其中添加了发泡剂,通常为铝粉。

5.稳定的材料在几小时内在高压釜中的饱和蒸汽气氛中从模具中取出后固化,从而获得其最终性能[14,15]。

- Foam concretes are given their structure for foaming by using foam generators or stirring up the cement paste using foaming agents and fast rotating pug mill mixers.

- The paste consists of the binder, usually cement, finely grounded quartzitic sand, water and foam generating admixtures.

- After moulding the foam, the concrete hardens under normal atmospheric conditions.

1.通过使用泡沫发生器或使用发泡剂和快速旋转的搅拌机搅拌器搅拌水泥浆,使泡沫混凝土具有发泡结构。

2.浆料由粘合剂组成,通常是水泥,精细研磨的石英砂,水和泡沫生成混合物。

3.模塑泡沫后,混凝土在正常大气条件下硬化。

- During the mechanical foaming procedure, a foam agent is added to the mortar.

- Numerous bubbles are mechanically introduced by high-speed mixers.

- A relatively unstable foam develops with an irregular structure and undefined void structures [11].

- In practice, a more usual manufacturing method is physical foaming.

-

A pre-manufactured foam consisting of water and chemical admixture is m

全文共28333字,剩余内容已隐藏,支付完成后下载完整资料

资料编号:[2242]

您可能感兴趣的文章

- 蒸养纤维掺杂高铁低钙水泥混凝土的抗海水冲磨性能研究文献综述

- TIPA对水泥-锂渣体系力学性能和水化性能的影响外文翻译资料

- TEA对锂渣-水泥复合粘结剂流变性能及水化性能的影响外文翻译资料

- 硫酸铝无碱液体促进剂的效果研究烷醇胺对硅酸盐水泥水化过程的影响外文翻译资料

- 新型C-A-S-H/PCE纳米复合材料:设计表征和对水泥水化的影响外文翻译资料

- 工业中碳捕获技术以及以水泥回转窑作为核心的吸附再生器外文翻译资料

- Ca/Al层状双氢氧化物的制备及其结构对水泥早期强度的影响外文翻译资料

- 蒸汽养护后混凝土养护方法对混凝土机械强度和透气性的影响外文翻译资料

- 含白云石或石灰石的偏高岭土水泥在相组成与抗压强度的异同外文翻译资料

- 与硅质铁尾矿结合的混凝土的耐久性外文翻译资料