添加Mg2Si烧结高导热氮化硅陶瓷毕业论文

2021-12-09 17:25:00

论文总字数:30752字

摘 要

Abstract Ⅱ

第1章 绪论 1

1.1课题背景 1

1.1.1 导热材料的性能要求 1

1.1.2 Si3N4陶瓷与AlN陶瓷的性能比较 1

1.1.3 Si3N4陶瓷在经济和环保上的优势 2

1.2 Si3N4陶瓷的导热机理 3

1.3影响Si3N4陶瓷热导率的因素. 4

1.3.1晶相 4

1.3.2晶格缺陷 4

1.3.3烧结助剂 4

1.3.4晶格氧含量 4

1.3.5晶界相 4

1.3.6外加β-Si3N4晶种 5

1.4 Si3N4陶瓷的主要制备工艺 5

1.5目前制备Si3N4导热陶瓷存在的问题 6

1.6本文的主要研究内容和方案 6

1.6.1 研究内容 6

1.6.2 研究方案 7

第2章 实验及分析测试方法 8

2.1 原料的选取 8

2.2 实验设备 9

2.3 实验工艺流程 11

2.3.1 实验工艺流程图 11

2.3.2 具体工艺操作及参数 12

2.4 结构与性能表征 12

2.4.1 致密度和真密度 12

2.4.2 XRD测试 13

2.4.3 微观形貌分析 13

2.4.4 热导率测定 13

2.4.5 透射电子显微镜分析 13

2.4.6 抗弯性能测试 14

2.4.7 硬度及断裂韧性测试 14

2.4.8 氧含量测定 15

第3章 结果与讨论 17

3.1引言 17

3.2实验方案 17

3.3 Mg2Si添加量对Si3N4陶瓷致密度的影响 18

3.4 Mg2Si添加量对晶粒尺寸的影响 21

3.5 Mg2Si添加量对Si3N4陶瓷导热性能的影响 22

3.6 退火时间的影响 24

3.7 Mg2Si添加量对Si3N4陶瓷力学性能的影响 27

第4章 结论 31

参考文献 32

致谢 34

附录A:本文所用原材料费用一览表 35

附录B:本文测试及分析费用一览表 36

摘要

氮化硅陶瓷(Si3N4)具有可以和氮化铝(AlN)陶瓷相媲美的高达320W*m-1*K-1理论热导率。同时由于其高强度、高韧性、高热导率、高热抗震性、耐磨损、耐腐蚀、无毒等优良性能,在航空航天、机械化工、海洋工程、装甲防护、人体植入材料等具有广泛应用。特别由于其极高的理论热导率,在电子封装材料,飞行器防护罩等方面应用前景广阔。所以研究合适的高热导率氮化硅陶瓷制备工艺对制造良好的散热材料有重要的意义。

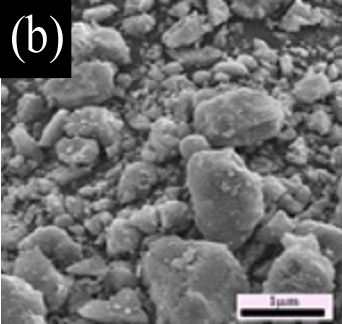

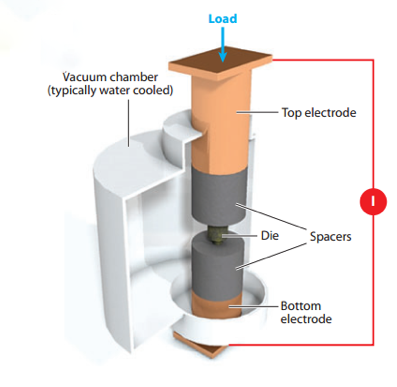

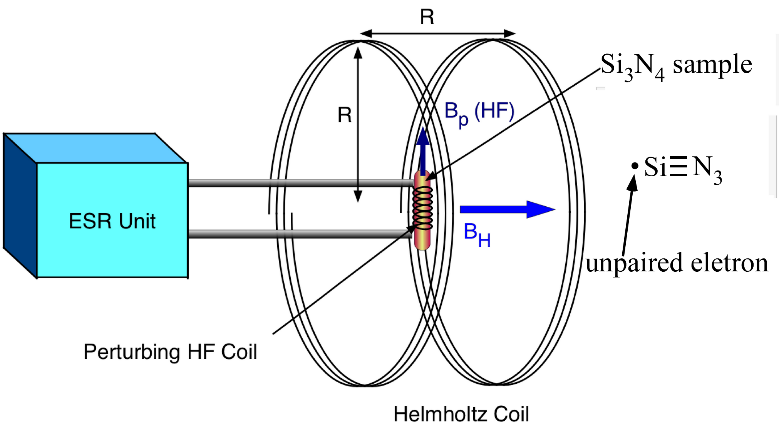

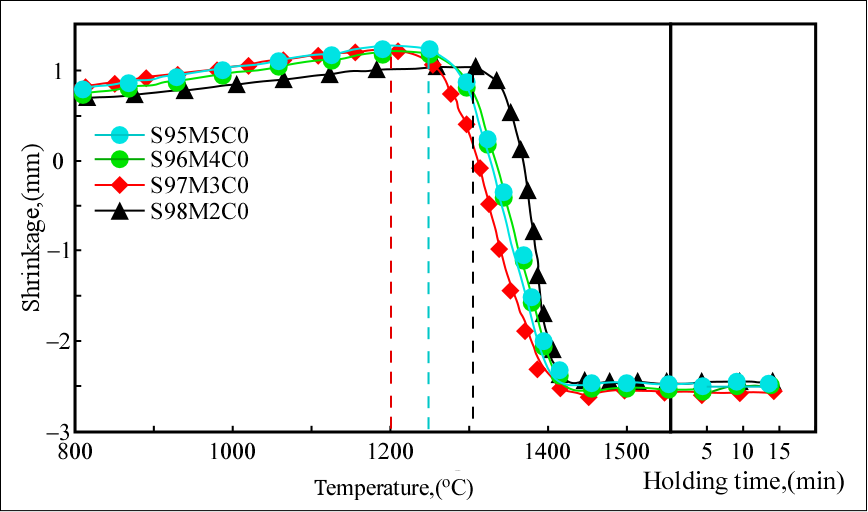

本文使用硅化镁(Mg2Si)做烧结助剂,等离子体活化烧结工艺(PAS)制备高导热Si3N4陶瓷。研究了在此条件下Si3N4陶瓷的致密化过程,不同Mg2Si添加量和不同退火工艺条件下对Si3N4陶瓷晶格氧含量,晶粒形态,热导率及力学性能的影响,并探究及影响的内在机理,以此为依据改善Si3N4陶瓷材料性能。

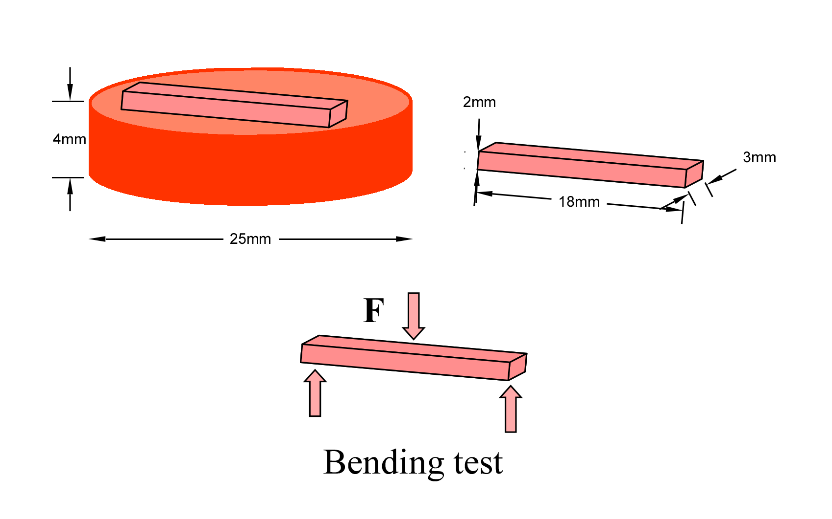

以高纯α-Si3N4粉末做原料,Mg2Si作烧结助剂,采用放电等离子体烧结工艺(PAS)制备导热Si3N4陶瓷。烧结升温阶段样品就已经完成致密化,XRD图谱显示α-Si3N4几乎完全转化为β-Si3N4。在相同烧结和退火工艺条件下,Mg2Si添加量为3wt%时制得Si3N4陶瓷热导率较高。不同Mg2Si含量的样品在相同的退火条件下热导率呈现不同的变化,Mg2Si含量较高的样品退火时间越长,其热导率略为下降,Mg2Si含量较低的样品退火时间越长其热导率则略为升高。通过对样品的抗弯强度测试,发现随Mg2Si含量的增加,Si3N4陶瓷的抗弯强度显下降趋势,在退火时间为6h时抗弯强度最高为846MPa,最低为622MPa,延长退火时间到12h,其变化趋势则相反,最低为550MPa,最高为590MPa,但仍明显低于退火6h时。但Si3N4陶瓷的韧性随Mg2Si含量增加及退火时间增加而变化的幅度及小。

关键词:Mg2Si;Si3N4陶瓷;热导率;弯曲强度;韧性

Abstract

Si3N4 ceramics have theoretical thermal conductivity up to 320W*m-1* k-1 comparable to AlN ceramics. Due to its high strength, toughness, thermal conductivity, high thermal shock resistance, wear resistance, corrosion resistance, non-toxic and other excellent properties,it is widely used in aerospace, mechanical,chemical engineering, Marine engineering, armor protection, human body implant materials, etc., .Specially,because of its high theoretical thermal conductivity, it has a broad application prospect in electronic packaging materials and aircraft protective covers, etc. Therefore, it is of great significance to study the preparation process of appropriate silicon nitride ceramics with high thermal conductivity for the manufacture of good heat dissipation materials.

In this paper, high thermal conductivity Si3N4 ceramics were prepared by using Mg2Si as sintering additives and plasma activated sintering process (PAS).Studying the densification process of Si3N4 ceramics in the condition of 1550oC,30 MPa and sintering for 15min . The effects of different Mg2Si addition amounts and different annealing processes on the lattice oxygen content, grain morphology, thermal conductivity and mechanical properties of Si3N4 ceramics were investigated, and the internal mechanism was explored to improve the properties of Si3N4 ceramic materials.

In this study, high purity α-Si3N4 powder was used as raw material and Mg2Si as sintering additives. Si3N4 ceramics with high thermal conductivity were prepared by plasma sintering process (PAS).It was found that the sample was completely densified at the sintering heating stage, and through XRD analysis, it can be seen that α-Si3N4 was almost completely transformed into β-Si3N4.In the same conditions of sintering and annealing process, the Si3N4 ceramic samples with 3wt% Mg2Si had the highest thermal conductivity. In the same annealing conditions ,thermal conductivity of samples with different contents of Mg2Si changed in different way.The higher samples of more Mg2Si annealing the longer, its thermal conductivity slightly dropped, when contain low amounts of Mg2Si samples annealing the longer its thermal conductivity is slightly elevated.Through the bending strength test of the samples, it was found that with the increase of Mg2Si content, the bending strength of Si3N4 ceramics decreased. When the annealing time was 6h, the bending strength was decreased from 846MPa to 622MPa with the increase of Mg2Si amount. When the annealing time was extended to 12h, the variation trend was opposite, it was incresed from 550MPa to 590MPa, and it was all significantly lower than which was annealed 6h.The toughness of Si3N4 ceramics changed just a little with the increase of Mg2Si content and annealing time.

Keywords: Mg2Si ;Si3N4 Ceramics ;Thermal ;Bending strenth;Vickers Hardness

请支付后下载全文,论文总字数:30752字

相关图片展示: